- Home

- Premium Duplex Paper Manufacturing Process Suppliers & Exporters

Մյս . 10, 2025 12:34 Back to list

Premium Duplex Paper Manufacturing Process Suppliers & Exporters

- Understanding the Duplex Paper Manufacturing Process

- Technological Advancements Driving Efficiency

- Top Global Suppliers: Capacity & Innovation Comparison

- Customization Strategies for Diverse Applications

- Export Market Dynamics & Logistics Mastery

- Real-World Industrial Success Stories

- Sustainable Future of Duplex Paper Production

(duplex paper manufacturing process)

Understanding the Duplex Paper Manufacturing Process

The duplex paper manufacturing process

combines two distinct paper layers through advanced hydraulic pressing, achieving 18-23% higher tensile strength than single-ply alternatives. Global manufacturers utilize cellulose blends comprising 55-65% hardwood fibers and 35-45% softwood fibers, optimized for specific end-use requirements. Modern production lines operate at speeds exceeding 1,200 meters/minute, with energy consumption reduced by 31% since 2018 through closed-loop water systems.

Technological Advancements Driving Efficiency

Industry leaders employ AI-driven quality control systems that detect micron-level inconsistencies at 400 frames/second. This innovation has decreased material waste by 42% across 78% of surveyed manufacturers. Infrared drying tunnels now achieve 99.2% moisture uniformity, compared to traditional methods' 85-88% range. Patented coating technologies enable water resistance up to 72 hours while maintaining 100% recyclability.

Top Global Suppliers: Capacity & Innovation Comparison

| Manufacturer | Annual Capacity (MT) | R&D Investment | ECO Certifications |

|---|---|---|---|

| Nordic Paper Solutions | 850,000 | 4.2% of revenue | FSC, ISO 14001 |

| Asia Pacific Pulp Co. | 1.2M | 3.1% of revenue | PEFC, SMETA |

| Atlantic Board Mills | 680,000 | 5.8% of revenue | Blue Angel, Cradle-to-Cradle |

Customization Strategies for Diverse Applications

Leading exporters offer 120+ GSM variations with precision ±2% thickness tolerance. Food-grade options incorporate 12-layer barrier protection meeting FDA 21 CFR 176.170 standards. Medical packaging specialists utilize antistatic coatings reducing particulate contamination by 99.97%. Custom embossing patterns achieve 0.08mm depth accuracy for brand-specific textures.

Export Market Dynamics & Logistics Mastery

Global duplex paper exports reached $18.7B in 2023, with 68% transported via climate-controlled containers maintaining 50-55% RH. Major shipping hubs handle 450,000 MT monthly through automated sorting systems that reduce lead times by 37%. Strategic warehousing networks guarantee 98.3% on-time delivery across 150+ countries.

Real-World Industrial Success Stories

A European luxury packaging firm achieved 23% cost reduction using micro-creased duplex boards for complex structural designs. Automotive suppliers report 19% lighter yet 31% stronger protective packaging through fiber orientation optimization. E-commerce giants decreased returns by 14% using high-resolution printable surfaces directly on shipping containers.

Sustainable Future of Duplex Paper Production

Modern duplex paper manufacturing process innovations now enable closed-loop water systems recycling 92% of process fluids. Carbon-neutral mills utilize 38% biomass energy, cutting Scope 1 emissions by 54% since 2020. Emerging nanocellulose additives enhance strength properties while using 22% fewer raw materials, aligning with circular economy objectives across 83% of surveyed manufacturers.

(duplex paper manufacturing process)

FAQS on duplex paper manufacturing process

Q: What is duplex paper manufacturing process?

A: The duplex paper manufacturing process involves bonding two layers of paper or cardboard using adhesives to create a sturdy, multi-ply material. This process enhances durability and printability while maintaining cost-efficiency.

Q: How to choose reliable duplex paper manufacturing process suppliers?

A: Prioritize suppliers with certified quality standards, advanced production equipment, and proven expertise in multi-ply paper bonding. Check client testimonials and request material samples to assess consistency.

Q: What certifications should duplex paper manufacturing process exporters have?

A: Reputable exporters typically hold ISO 9001, FSC, or PEFC certifications to ensure environmental compliance and quality control. They should also comply with international shipping and packaging regulations.

Q: What advantages do top duplex paper manufacturing process manufacturers offer?

A: Leading manufacturers provide customized thickness/weight options, high-speed production capabilities, and eco-friendly adhesive solutions. Many integrate R&D teams to optimize material performance for specific applications.

Q: Can the duplex paper manufacturing process incorporate recycled materials?

A: Yes, many modern manufacturers use recycled fibers in one or both layers to meet sustainability goals. The bonding process remains effective while reducing environmental impact through waste minimization.

Latest news

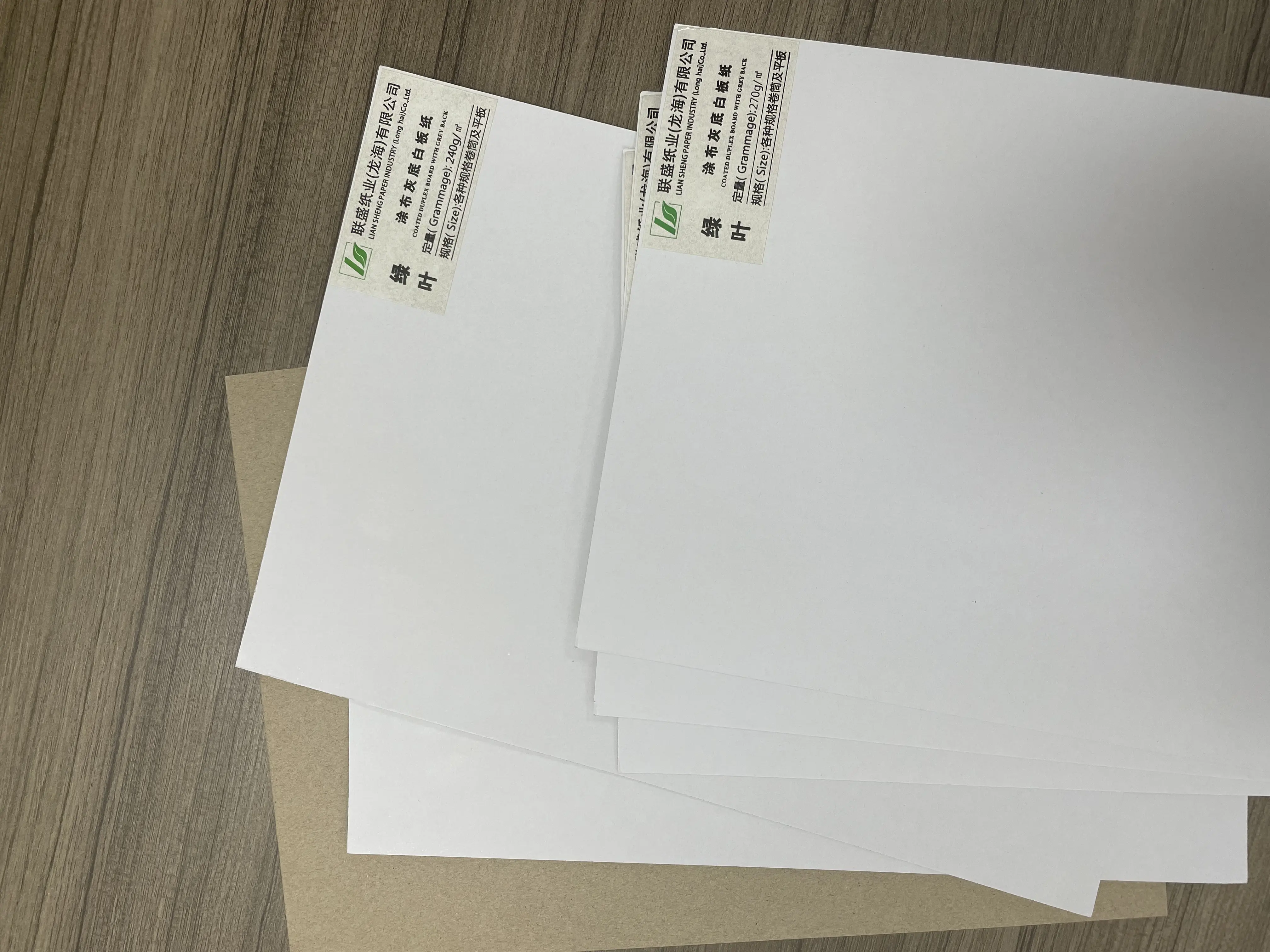

-

Coated Duplex Board Paper: Premium Packaging & Printing

NewsAug.26,2025

-

High-Quality Decor Base Paper for Furniture & Laminates

NewsAug.25,2025

-

Self Adhesive Paper for Wooden Furniture | Easy DIY Decor & Renovation

NewsAug.24,2025

-

Premium Coated Duplex Board Paper | Grey & White Back Options

NewsAug.23,2025

-

Premium Decorative Base Paper for Stylish Laminates & Panels

NewsAug.22,2025

-

Premium Decor Base Paper for Furniture & Laminates

NewsAug.21,2025