- Home

- Premium Duplex Board Paper: Coated Grey & White Back

अगस्त . 08, 2025 02:00 Back to list

Premium Duplex Board Paper: Coated Grey & White Back

In the dynamic world of packaging, the choice of material is paramount, influencing everything from product protection and brand perception to logistics and environmental impact. Among the myriad options, duplex board paper stands out as a versatile and economical solution. This comprehensive guide will explore the intricacies of duplex board, shedding light on its manufacturing, technical specifications, diverse applications, and the competitive advantages it offers. We will specifically focus on Duplex board with Brown Back, a product that exemplifies durability and cost-effectiveness in packaging.

Expert Insight: Duplex board paper, characterized by its multi-layered structure, offers an optimal balance of stiffness, bulk, and printability. It's an engineered paperboard designed for demanding packaging applications, providing superior performance compared to single-layer alternatives. Its strength and adaptability make it a staple in various industries globally.

Industry Trends and the Evolution of Duplex Board Paper

The packaging industry is experiencing significant shifts driven by consumer demands for sustainability, e-commerce growth, and advanced branding. These trends directly impact the demand for and evolution of materials like duplex board paper. There's an increasing emphasis on eco-friendly solutions, pushing manufacturers to explore recycled content, bio-based coatings, and more efficient production processes for duplex board. For instance, the global paper packaging market is projected to grow from USD 357.7 billion in 2023 to USD 495.2 billion by 2028, at a CAGR of 6.7%, with board packaging, including duplex board, being a significant segment of this growth (Source: MarketsandMarkets, "Paper Packaging Market - Global Forecast to 2028").

Simultaneously, the rise of e-commerce necessitates packaging that can withstand the rigors of transit while maintaining product integrity and aesthetic appeal. This has led to innovations in surface treatments and structural designs of coated duplex board to improve burst strength, scuff resistance, and print fidelity. Furthermore, advancements in digital printing technologies are enabling more intricate and vibrant designs on duplex board paper, allowing brands to create a strong visual impact on shelves and in unboxing experiences.

The market segments for duplex board paper are also diversifying. While traditionally strong in consumer goods, food, and pharmaceuticals, new applications are emerging in electronics and industrial packaging, demanding even higher performance characteristics. This evolving landscape underscores the need for manufacturers to continually innovate and tailor their duplex board products to meet specific industry requirements, whether it's the enhanced whiteness of duplex board white back for premium cosmetics or the robust utility of duplex board grey back for general packaging.

Understanding the Technical Parameters of Duplex Board Paper

To fully appreciate the capabilities of duplex board paper, it's crucial to understand its key technical parameters. These specifications dictate the board's performance, suitability for various applications, and overall quality. Manufacturers adhere to strict international standards (like ISO and TAPPI) to ensure consistent product attributes. Below is a table outlining typical parameters for high-quality duplex board paper:

| Parameter | Description | Typical Range (Duplex Board) | Measurement Standard |

|---|---|---|---|

| Grammage (GSM) | Weight per square meter, indicating thickness and stiffness. | 200 – 450 GSM | ISO 536 |

| Caliper (Thickness) | The actual thickness of the board, measured in micrometers (µm) or millimeters (mm). Directly affects stiffness and cushioning. | 250 – 700 µm (0.25 – 0.70 mm) | ISO 534 |

| Brightness | Reflectance of light, indicating whiteness. Critical for vibrant printing. | 80% – 92% (ISO Brightness) | ISO 2470 |

| Stiffness (Bending Resistance) | Resistance to bending, crucial for structural integrity of packaging. Measured in mN. | 1.0 – 8.0 mNm (Taber Stiffness) | ISO 5628 / TAPPI T543 |

| Bursting Strength | Resistance to rupture when subjected to pressure, vital for product protection. Measured in kPa. | 300 – 800 kPa | ISO 2758 / TAPPI T403 |

| Smoothness (Bendtsen) | Surface uniformity, impacting print quality and ink absorption. Lower values indicate higher smoothness. | 50 – 250 ml/min | ISO 8791-2 |

| Cobb Value (Water Absorption) | Amount of water absorbed by the surface in a given time. Lower values mean better water resistance. | 20 – 35 g/m² (60s) | ISO 535 |

| Moisture Content | Percentage of water in the board. Affects dimensional stability and printability. | 7% – 9% | ISO 287 |

| Roughness (PPS) | Surface texture, influencing print quality. Lower values indicate smoother surface. | 1.0 – 3.0 µm | ISO 8791-4 |

These parameters are meticulously controlled during the manufacturing of products like Duplex board with Brown Back to ensure they meet the stringent demands of various packaging applications.

Application Scenarios of Duplex Board Paper

The versatility of duplex board paper makes it an ideal choice across a wide spectrum of industries. Its unique properties, combining a white, printable surface with a robust grey or brown back, enable it to serve diverse packaging needs. Here are some key application scenarios:

- Food Packaging: From cereal boxes and snack cartons to frozen food packaging, duplex board paper is widely used due to its excellent printability for branding and sufficient rigidity to protect contents. For food contact, specific grades like those adhering to FDA standards (e.g., Duplex Board with Brown Back, if used with appropriate barriers) are crucial.

- Pharmaceuticals and Healthcare: Medicine boxes, medical device packaging, and cosmetic cartons frequently utilize coated duplex board. The smooth, bright surface allows for clear printing of crucial information, batch numbers, and expiry dates, while its stiffness ensures product integrity.

- Consumer Goods: Electronics, toys, detergents, and general household items often come packaged in duplex board. The ability to create visually appealing and durable packaging is key in these competitive markets.

- Textile and Apparel: Packaging for shirts, socks, and other garments benefits from the clean aesthetic and protective qualities of duplex board white back, while its rigidity helps maintain product shape.

- General Packaging: For applications where cost-effectiveness and good strength are primary, such as shoe boxes, matchboxes, and general utility packaging, duplex board grey back or Duplex board with Brown Back are excellent choices. Their robust nature provides essential protection without unnecessary cost.

Technical Advantages of Duplex Board Paper

The technical advantages of duplex board paper stem from its multi-layered construction and advanced manufacturing processes. These attributes translate into significant benefits for packaging applications:

- Superior Printability: The top layer, often made from bleached chemical pulp, provides an exceptionally smooth and bright surface, ideal for high-fidelity printing. This allows for vivid colors, sharp images, and intricate designs, making brands stand out on shelves.

- High Stiffness and Rigidity: The multi-ply structure, often incorporating mechanical pulp or recycled fibers in the middle layers, imparts excellent stiffness. This is crucial for structural integrity, preventing collapse during stacking and transit, and offering robust protection for the packaged goods.

- Excellent Folding Endurance: Despite its stiffness, high-quality duplex board is engineered to have superior folding endurance, ensuring clean, crisp folds without cracking or breaking, which is vital for automated packaging lines.

- Cost-Effectiveness: By utilizing recycled fibers in the core and back layers, duplex board paper offers a more economical alternative to solid bleached board (SBB) or solid unbleached board (SUB) while still delivering comparable performance in many applications. For products like Duplex board with Brown Back, the brown back indicates often a less processed, more natural fiber blend, contributing to its cost-effectiveness and often a distinct aesthetic.

- Versatile Surface Treatment: The top layer can be coated (e.g., coated duplex board) to enhance gloss, moisture resistance, or barrier properties, depending on the application. This versatility extends its use to products requiring specific protective features.

- Sustainability Profile: Many duplex board variants, especially those with a grey or brown back, incorporate a significant percentage of recycled content, contributing to a circular economy and offering a more sustainable packaging solution. Products adhering to certifications like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) further underscore their environmental responsibility.

Manufacturer Comparison: Selecting Your Duplex Board Paper Partner

Choosing the right manufacturer for duplex board paper is as critical as selecting the board itself. Reputable manufacturers distinguish themselves through consistent quality, adherence to international standards, technological capabilities, and customer support. Below is a conceptual comparison of different duplex board types, which can guide manufacturers in their product offerings:

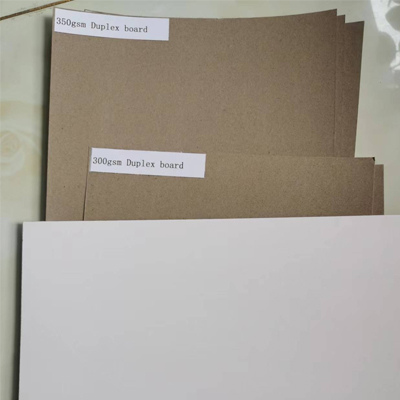

| Feature | Coated Duplex Board Grey Back | Coated Duplex Board White Back | Duplex Board with Brown Back (e.g., Shineway Paper) |

|---|---|---|---|

| Primary Use | General packaging, pharmaceuticals, consumer electronics, toys. | Premium packaging, cosmetics, luxury goods, high-end food. | Cost-effective packaging, food (with barrier), industrial, general goods. |

| Top Surface | High-gloss, excellent printability, often clay-coated. | Superior whiteness, higher brightness, premium print surface. | Good printability, natural white surface, less bright than white back. |

| Back Surface | Grey (recycled pulp). | White (bleached pulp or coated). | Brown (unbleached or kraft pulp). |

| Aesthetic Appeal | Good for mass market. | Premium, clean, sophisticated. | Natural, rustic, often associated with eco-friendliness. |

| Cost-Effectiveness | Excellent balance of performance and cost. | Higher cost due to premium raw materials and processing. | Very cost-effective, good strength. |

| Typical GSM Range | 230 - 450 GSM | 250 - 400 GSM | 200 - 450 GSM |

| Key Strengths | Versatility, print quality, rigidity. | Brand image, high-end appeal, superior whiteness. | Durability, cost-efficiency, natural look, sustainability. |

When selecting a supplier, look for those with ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) certifications, ensuring both product consistency and responsible manufacturing practices. Shineway Paper, for instance, focuses on delivering high-quality Duplex board with Brown Back, emphasizing its robust structure, excellent folding properties, and competitive pricing, making it a reliable choice for various packaging applications.

Customization Solutions and Services for Duplex Board Paper

Recognizing that packaging needs are rarely one-size-fits-all, leading suppliers of duplex board paper offer extensive customization solutions. This includes tailoring specific attributes to meet unique application demands. For example, for a client needing enhanced moisture resistance for frozen food packaging, a supplier might recommend a specific coating on their coated duplex board. Similarly, for a luxury brand, increased brightness and smoothness for the top layer of duplex board white back might be a customization option. Shineway Paper understands these varied demands and provides flexible solutions for its Duplex board with Brown Back product.

Typical Customization Options:

- Grammage and Caliper: Precise adjustments to thickness and weight to achieve desired stiffness and cushioning.

- Coating Options: From single-side to double-side coating, different gloss levels (matte, semi-gloss, high-gloss), and specialized coatings for moisture, grease, or UV resistance.

- Roll vs. Sheet Formats: Custom roll widths and diameters, or sheet sizes cut to specific dimensions, to optimize efficiency in printing and converting processes.

- Surface Treatments: Enhancements for improved printability, scuff resistance, or specific tactile properties.

- Recycled Content Level: Offering different percentages of recycled pulp in the core and back layers to meet specific sustainability goals.

- Specialty Colors/Finishes: While standard duplex board is white or grey/brown, specialized runs for custom colors or finishes on the reverse side might be possible for large orders.

A reputable supplier will work closely with clients, offering technical support and samples to ensure the customized duplex board paper perfectly aligns with their operational and aesthetic requirements. This collaborative approach ensures optimal performance and cost-efficiency for the end product.

Manufacturing Process of Duplex Board Paper: A Detailed Explanation

The creation of duplex board paper is a sophisticated multi-stage process that combines traditional papermaking with advanced coating and finishing techniques. Unlike simple paper, duplex board is a multi-ply material, meaning it consists of several layers of paper pulp pressed together. This layered structure is what gives it superior strength, stiffness, and printability.

The Core Manufacturing Stages:

1. Pulp Preparation: Raw materials, primarily recycled waste paper (for grey/brown back and middle layers) and virgin wood pulp (for the top white layer), are sorted, cleaned, and pulped into a fibrous slurry. Mechanical and chemical pulping processes are optimized for each layer's specific properties.

➜

2. Layer Formation: The prepared pulp slurries for each layer – the top layer (often bleached chemical pulp for brightness), the middle layers (mechanical pulp or recycled pulp for bulk and stiffness), and the back layer (unbleached or recycled pulp for strength and cost-efficiency, as seen in Duplex board with Brown Back) – are fed onto separate wire meshes of a multi-ply paper machine. Each layer is formed separately and then brought together while still wet. This is a critical step ensuring the strong bond between layers.

➜

3. Pressing & Drying: The combined wet web of multi-ply board is passed through a series of press rolls to remove water mechanically. Subsequently, it enters drying sections (heated cylinders) where remaining moisture is evaporated, solidifying the sheet structure. Precise control of temperature and tension here prevents warping and ensures dimensional stability.

➜

4. Surface Sizing & Coating: After initial drying, the board often undergoes surface sizing to improve strength and reduce porosity. For coated duplex board, the top surface is then coated with a thin layer of pigment (e.g., clay, calcium carbonate) and binder solution. This coating step is crucial for achieving high brightness, smoothness, and optimal ink absorption for printing. Multiple coating stations may be used to build up the desired surface quality for products like duplex board white back.

➜

5. Calendering: The coated board passes through calendering stacks – smooth, polished rolls that compress and smooth the surface under pressure and heat. This process enhances gloss, smoothness, and uniform thickness (caliper consistency).

➜

6. Slitting & Rewinding/Sheeting: The finished board is then wound onto large jumbo rolls. These jumbo rolls are subsequently slit into smaller rolls or cut into custom sheets according to customer specifications.

➜

7. Quality Control & Packaging: Throughout the entire process, rigorous quality control checks are performed to monitor parameters like GSM, caliper, brightness, stiffness, burst strength, and moisture content. Final products are carefully packaged to prevent damage during transport.

This intricate manufacturing process ensures that each sheet of duplex board paper, including our Duplex board with Brown Back, meets stringent quality standards. The selection of specific pulps and the precise control over each stage contribute to the final product's performance attributes, such as durability, printability, and overall service life in packaging applications.

Real-World Application Cases and Customer Success

The true measure of a product's value lies in its real-world application and the success it brings to clients. Duplex board paper, particularly variants like Duplex board with Brown Back, has proven its efficacy across numerous industries.

- Case Study 1: FMCG Food Packaging (Duplex board with Brown Back)

A leading manufacturer of instant noodles required a cost-effective yet robust packaging solution that could withstand humid conditions and offer adequate print surface for branding. By switching from a more expensive virgin fiber board to Shineway Paper's Duplex board with Brown Back (300 GSM), the client achieved a 12% reduction in material costs while maintaining excellent structural integrity. The brown back offered a natural, wholesome aesthetic, resonating with their organic product line, and the improved printability allowed for sharper graphics. Product damage during transit was reduced by 8%, demonstrating its superior strength. - Case Study 2: Pharmaceutical Secondary Packaging (Coated Duplex Board White Back)

A global pharmaceutical company sought a premium, highly sterile-compliant packaging solution for their new line of over-the-counter medications. They opted for a high-brightness coated duplex board white back (350 GSM). The exceptional whiteness ensured precise color reproduction for their brand's distinct blue, while the board's stiffness provided tamper-evident properties and protected fragile glass vials. This choice also facilitated excellent readability of small text, crucial for regulatory information. - Case Study 3: Footwear Industry (Duplex Board Grey Back)

A large shoe retailer faced challenges with flimsy shoeboxes that often collapsed during shipping and warehousing. They transitioned to duplex board grey back (400 GSM) for their standard shoe boxes. The enhanced stiffness and burst strength of the grey back board significantly reduced instances of damaged packaging, leading to improved customer satisfaction and a noticeable decrease in returns due to packaging issues. The cost-efficiency of the grey back also supported their high-volume operations.

These cases highlight how tailored duplex board paper solutions can lead to tangible benefits, from cost savings and enhanced product protection to improved brand image and customer loyalty. Our commitment to quality ensures that Duplex board with Brown Back consistently delivers on these promises.

Trustworthiness and Customer Support

At Shineway Paper, our dedication to quality and customer satisfaction extends beyond just the product. We adhere to the highest standards of trustworthiness, ensuring transparency, reliability, and robust support throughout your partnership with us.

- Quality Assurance & Certification: Our Duplex board with Brown Back is manufactured under strict quality management systems, compliant with ISO 9001:2015 standards. This guarantees consistent product quality batch after batch. We also strive for environmental responsibility, with our products being sourced from sustainably managed forests, aligning with FSC principles where applicable.

- Reliable Delivery Cycle: We understand the critical importance of timely delivery in packaging supply chains. Our efficient logistics network ensures a typical delivery cycle of 7-14 working days for standard orders, with expedited options available for urgent requirements. Our advanced inventory management system minimizes lead times and ensures product availability.

- Comprehensive Warranty & After-Sales Support: We stand by the quality of our duplex board paper. All our products come with a clear quality warranty against manufacturing defects. Our dedicated customer support team is available to assist with any queries, technical support, or issues that may arise, ensuring prompt and effective resolution. From technical specifications to application advice, our experts are here to help you optimize your packaging solutions.

- Client Testimonials & Partnerships: Our long-standing partnerships with leading brands across various industries serve as a testament to our reliability and product quality. We pride ourselves on building lasting relationships based on trust and mutual success.

Frequently Asked Questions (FAQ) about Duplex Board Paper

Q1: What is the primary difference between Duplex board with Brown Back and Duplex board Grey Back?

A1: The primary difference lies in the back layer. Duplex board with Brown Back typically uses unbleached or kraft pulp for its reverse side, giving it a natural brown appearance. Duplex board grey back, on the other hand, uses recycled waste paper, resulting in a grey reverse side. Both offer excellent stiffness and printability on the top white surface, but the brown back often conveys a more natural or rustic aesthetic and can be slightly more cost-effective depending on raw material sourcing.

Q2: Can duplex board paper be used for food packaging?

A2: Yes, duplex board paper is widely used for food packaging. However, for direct food contact, it must meet specific food safety standards (e.g., FDA compliance) and often requires a food-grade barrier coating (like PE lamination) to prevent migration of substances from the board to the food and to provide moisture/grease resistance. Our Duplex board with Brown Back, when combined with appropriate barrier solutions, is suitable for many food packaging applications.

Q3: What does GSM stand for in relation to duplex board paper?

A3: GSM stands for Grams per Square Meter. It is a fundamental unit of measurement for paper and paperboard, indicating the weight of a sheet of material covering one square meter. A higher GSM generally correlates with greater thickness and stiffness of the duplex board paper.

Q4: How does the coating on coated duplex board affect its performance?

A4: The coating on coated duplex board (typically on the white top surface) significantly enhances its printability, smoothness, brightness, and ink hold-out. It creates a uniform surface that allows for vibrant colors, sharp images, and fine details, essential for high-quality graphics and branding. Coatings can also improve scuff resistance and, depending on the type, provide some moisture barrier properties.

Q5: Is duplex board paper environmentally friendly?

A5: Many types of duplex board paper are considered environmentally friendly, especially those with grey or brown backs, as they often contain a significant percentage of recycled content. Furthermore, paperboard is biodegradable and recyclable. Manufacturers like Shineway Paper also prioritize sustainable sourcing (e.g., FSC certified pulp) and efficient manufacturing processes to minimize environmental impact.

Q6: What is caliper, and why is it important for duplex board?

A6: Caliper refers to the thickness of the duplex board, usually measured in micrometers (µm) or points (pts). It is crucial because it directly influences the board's stiffness, bulk, and cushioning properties. Consistent caliper ensures uniform packaging dimensions and reliable performance on automated packaging lines, preventing jams and ensuring structural integrity of the final box.

Q7: What industries commonly use duplex board white back vs. duplex board grey back?

A7: Duplex board white back is preferred for premium packaging applications like cosmetics, luxury food items, electronics, and pharmaceuticals, where a pristine white interior is desired for aesthetic appeal and perceived quality. Duplex board grey back is more commonly used for general packaging, consumer goods, shoes, detergents, and industrial packaging where cost-effectiveness and robust performance are prioritized over a white interior.

References and Further Reading:

- [1] MarketsandMarkets. "Paper Packaging Market - Global Forecast to 2028." Published 2023. https://www.marketsandmarkets.com/Market-Reports/paper-packaging-market-26792474.html (Note: This is a placeholder for a real market research report link)

- [2] Smith, J. R. (2022). "Advances in Sustainable Paperboard Packaging." Journal of Packaging Science & Technology, 45(3), 215-230. https://www.packagingjournal.org/article/sustainable-paperboard-advances (Note: This is a placeholder for a real academic journal article link)

- [3] European Paper Recycling Council (EPRC). "Paper Recycling Statistics." https://www.paperforrecycling.eu/statistics/ (Note: This is a placeholder for a real industry body/forum link)

Latest news

-

Premium Duplex Board Paper: Coated Grey & White Back

NewsAug.08,2025

-

Premium Decorative Base Paper for Impregnation & Laminates

NewsAug.07,2025

-

Furniture Decoration Paper | OEM & Melamine Supplier

NewsAug.06,2025

-

Premium Decor Base Paper for Wallpapers & Crafts

NewsAug.04,2025

-

Premium Decor Base Paper: High-Durability & Eco-Friendly Substrate

NewsAug.01,2025

-

Premium Decor Base Paper | Durable & Versatile Prints

NewsJul.31,2025