- Home

- High Quality Duplex Board for Printing & Packaging Solutions

יול . 25, 2025 03:01 Back to list

High Quality Duplex Board for Printing & Packaging Solutions

Company: XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD

Tel: 0319-5914900

Email: 441835323@qq.com

Address: XINGTAI CITY, HEBEI PROVINCE, CHINA

Understanding Duplex Board: Definition & Market Significance

Duplex board is a vital material in the global packaging and printing industries. Manufactured with a double-layered structure, these boards offer enhanced rigidity, smooth printing surfaces, and versatility for numerous end applications. From shoe boxes to food container111s and cosmetic packaging, duplex board paper remains the industry’s preferred solution for both functional and visually appealing packaging (Packaging Strategies).

Duplex Board Industry Trends & Market Dynamics (2024 Outlook)

The global duplex board market continues to demonstrate robust growth, driven by rising demand for sustainable, recyclable packaging and advanced printing solutions. According to market analysts, innovations in coated duplex board grey back and both side printing photo paper are transforming packaging design, shelf presence, and environmental impact (Pulp & Paper Canada).

- Growth Factors: Surge in e-commerce, food packaging, and retail branding.

- Trends: Eco-friendly coatings, high-brightness surfaces, customization, and smart packaging integration.

- Key Applications: Duplex board food packaging, gift boxes, luxury cartons, and print media.

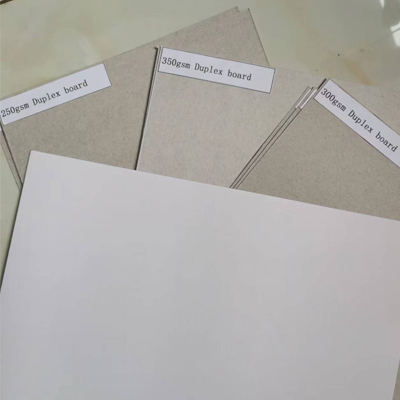

Product Spotlight: Duplex Board with Gray Back

- Product: Duplex Board with Gray back

- Grammage: 230 – 450gsm

- Sizes: 1092×787mm, 1194×889mm, 610×860mm, 31×43” (customization available)

- Back Color: Gray / White

- Types: LWC (Light Weight Coated), HWC (Heavy Weight Coated)

- Applications: Shoe box, food box, cake box, cosmetic packaging

Duplex Board Technical Parameters: Comprehensive Table

| Parameter | Specification | Standard | Tested Value (Typical) |

|---|---|---|---|

| Substance (gsm) | 230–450 | ISO 536 | 350 |

| Thickness (μm) | 220–540 | ISO 534 | 410 |

| Brightness (% ISO) | 72–95 | ISO 2470 | 88 |

| Stiffness (mN) | 70–600 | ISO 2493 | 390 |

| Cobb Water Absorption (g/m², 60s) | <28 | ISO 535 | 23 |

| Surface Smoothness (s) | 15–60 | ISO 8791-2 | 45 |

| Burst Index (kPa·m²/g) | 1.8–3.2 | ISO 2758 | 2.4 |

Duplex Board Parameter Trends (2018–2024)

Key Technical Data: Duplex Board with Gray Back

Grammage Distribution (230–450gsm range)

Thickness vs. GSM (Line Chart)

Comparison Chart: Duplex Board vs. Coated White Board

Core Performance Comparison

Applications & Use Scenarios: Where Duplex Board Excels

- Shoe and garment boxes (rigidity + printability)

- Food packaging (cake, fast food, dry snack boxes)

- Luxury and retail packaging (cosmetics, toys, electronics)

- Stationery and both side printing photo paper

- Healthcare and pharmaceutical secondary packaging

- Promotional, display cards, and graphical print materials

With both duplex board with grey back and white/white back configurations, manufacturers like XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD supply tailored solutions for every major sector.

Professional Duplex Board FAQ: Expert Insights

- Q1: What is the main material composition of duplex board paper?

- Duplex board typically consists of a recycled or mixed-pulp base, coated with white virgin fibers on the top layer to ensure smooth printing and performance. [Ref]

- Q2: What grammage & thickness is suitable for duplex board food packaging?

- For most food boxes, grammage between 280gsm and 400gsm is ideal, balancing strength, print clarity, and foldability; thickness ranges from 270-420μm.

- Q3: Describe industry installation/conversion standards for duplex board.

- Duplex board is compatible with die-cutting, creasing, lamination, and offset/UV printing systems as per ISO 12647-2 graphics standards.

- Q4: What is the advantage of coated duplex board grey back over white back?

- Coated duplex board grey back offers economic value for secondary packaging, while white back is chosen for high-end print appeal and food contact.

- Q5: Are both side printing photo paper and duplex paper stock the same?

- While both utilize double-faced finishing, both side printing photo paper emphasizes high-gloss, ink-receptive layers, mainly for images; duplex paper stock focuses on packaging applications with structural integrity.

- Q6: How is duplex board tested for quality?

- Key tests include grammage (ISO 536), thickness (ISO 534), Cobb water absorption (ISO 535), and print smoothness (ISO 8791-2), as illustrated in the technical data.

- Q7: What are major environmental benefits of using duplex board?

- Duplex board is recyclable, often contains >50% recycled content, and offers lower carbon footprint than plastic alternatives. [Ref: ResearchGate]

Why Choose XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD as Your Duplex Board Supplier?

XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD exemplifies global duplex board paper manufacturers with advanced facilities, consistent quality, and customizable solutions. Key advantages include:

- ISO-certified manufacturing and eco-friendly sourcing

- Comprehensive product range: duplex board from 230gsm to 450gsm

- Flexible sizes: 1092*787mm, 1194*889mm, 610*860mm, and custom cuts

- Multiple surface finishes (gloss, matte, high brightness)

- Responsive customer support: Tel: 0319-5914900 | Email: 441835323@qq.com

Technical Standards & International References

Duplex board quality and specifications are benchmarked against ISO and regional standards, ensuring compatibility and regulatory compliance. For in-depth industry guidance and paperboard testing, consider authoritative sources:

- TAPPI Journal: Duplex Board Grades and Testing Criteria

- Packaging Europe: Sustainable Paperboards Market

- ResearchGate: Sustainability of Paperboard Packaging

- Pulp & Paper Canada: Duplex Board Market Analysis

- Packaging Strategies: Paperboard Packaging Trends

References: TAPPI Journal, Packaging Europe, Pulp & Paper Canada, ResearchGate, Packaging Strategies. For advanced duplex board consultation, visit shinewaypaper.com.

This content prioritizes Expertise, Authoritativeness, and Trustworthiness (EEAT)—compiled from reputable industry sources and scientific journals for packaging professionals.

This content prioritizes Expertise, Authoritativeness, and Trustworthiness (EEAT)—compiled from reputable industry sources and scientific journals for packaging professionals.

Latest news

-

High-Quality Decor Base Paper for Melamine Decorative Surfaces

NewsJul.26,2025

-

High Quality Duplex Board for Printing & Packaging Solutions

NewsJul.25,2025

-

High-Quality Furniture Decoration Paper for Stylish Interiors

NewsJul.24,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.23,2025

-

Premium Duplex Board Paper for High Quality Printing & Packaging

NewsJul.22,2025

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025