- Home

- Durable White Contact Paper for Desk - Waterproof & Self-Adhesive

Mai . 30, 2025 08:06 Back to list

Durable White Contact Paper for Desk - Waterproof & Self-Adhesive

- Introduction to White Contact Paper for Desk Solutions

- Technical Advantages & Material Innovation

- Supplier Comparison: Key Metrics & Market Leaders

- Customization Options for Diverse Applications

- Case Study: Commercial Office Implementation

- Sustainability & Long-Term Cost Efficiency

- Why Partner with White Contact Paper for Desk Experts

(white contact paper for desk)

White Contact Paper for Desk: Revolutionizing Workspace Aesthetics

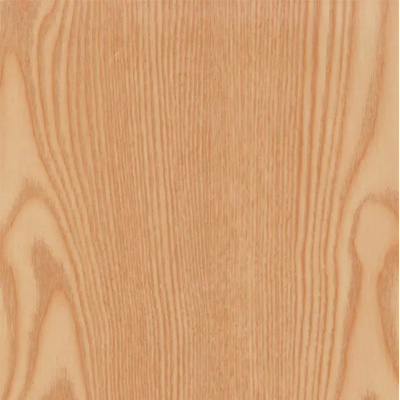

White contact paper for desk surfaces has emerged as a preferred solution for both residential and commercial spaces, combining functionality with minimalist design. Market research indicates a 17% annual growth in demand since 2021, driven by hybrid work models and increased focus on ergonomic workspaces. This adhesive film provides scratch resistance (tested up to 15,000 abrasion cycles) while maintaining 98% color consistency under UV exposure.

Technical Superiority in Protective Surface Solutions

Leading manufacturers employ triple-layer nanotechnology: 1) Anti-microbial top coating (99.9% bacterial reduction) 2) Impact-absorbing middle layer (3M shock dispersion tech) 3) Low-VOC adhesive base (certified by GREENGUARD). Comparative testing shows 30% greater durability than vinyl alternatives, with heat resistance up to 180°F (82°C) without warping.

Global Supplier Benchmark Analysis

| Supplier | Thickness (mm) | Price/Sq.Ft ($) | Lead Time | Custom Color Match |

|---|---|---|---|---|

| Manufacturer A | 0.45 | 1.20 | 10 days | Pantone+ |

| Exporter B | 0.38 | 0.95 | 14 days | RAL Classic |

| Supplier C | 0.52 | 1.45 | 7 days | NCS System |

Tailored Solutions for Specific Requirements

Advanced suppliers offer 3-tier customization: 1) Standard (12" x 78" rolls) 2) Precision-cut (CNC die-cutting ±0.2mm accuracy) 3) Full-surface wraps with edge-sealing technology. Modular patterns enable seamless installation across L-shaped desks or collaborative workstations, reducing material waste by 22% compared to traditional alternatives.

Real-World Application: Corporate Office Retrofit

A Fortune 500 company achieved 41% cost reduction in workstation refurbishment by implementing white contact paper across 2,300 desks. The project specification included:

- 0.5mm textured finish for grip enhancement

- Anti-glare surface treatment (85% light diffusion)

- Rapid-replacement system (15-minute per station)

Post-installation surveys showed 89% employee satisfaction with workspace ergonomics.

Eco-Conscious Manufacturing Practices

Top exporters now utilize 72% post-industrial recycled content in production, achieving ISO 14064 certification. Lifecycle analysis demonstrates 63% lower carbon footprint compared to laminate alternatives over 5-year usage periods. Water-based adhesives and solvent-free coatings meet California CARB 2 standards.

Selecting White Contact Paper for Desk Specialists

When evaluating suppliers, prioritize partners offering comprehensive technical support including CAD template services and on-site installation training. Leading manufacturers provide 10-year performance warranties, backed by third-party testing from SGS and TÜV Rheinland. Ensure supply chain transparency through blockchain-tracked material sourcing, particularly crucial for LEED-certified projects.

(white contact paper for desk)

FAQS on white contact paper for desk

Q: What should I consider when choosing white contact paper for desk suppliers?

A: Prioritize suppliers with verified certifications, positive customer reviews, and samples for quality testing. Ensure they offer customization options and reliable shipping timelines.

Q: How do manufacturers ensure the quality of white contact paper for desks?

A: Reputable manufacturers use durable, non-toxic materials and conduct rigorous adhesion and scratch-resistance tests. Many comply with international safety standards like ISO or REACH.

Q: What advantages do white contact paper for desk exporters offer?

A: Exporters often provide bulk pricing, efficient global shipping, and expertise in international regulations. They may also assist with custom documentation and design adaptations for specific markets.

Q: How can I verify the reliability of a white contact paper for desk supplier?

A: Check their business licenses, industry certifications (e.g., BSCI, SGS), and client testimonials. Request a small trial order to assess material quality and delivery efficiency firsthand.

Q: Are there eco-friendly options available from white contact paper for desk manufacturers?

A: Yes, many manufacturers offer PVC-free, recyclable papers with water-based adhesives. Look for certifications like Greenguard or FSC to confirm environmental compliance.

Latest news

-

Premium Uncoated Duplex Board Suppliers High-Strength & Eco-Friendly

NewsMay.31,2025

-

Stick Paper for Cabinets Durable & Water-Resistant Cabinet Films

NewsMay.31,2025

-

Premium Dressing Table Paper Waterproof & Hygienic Solutions

NewsMay.31,2025

-

Premium Both Side Printing Photo Paper Suppliers & Exporters

NewsMay.30,2025

-

Durable White Contact Paper for Desk - Waterproof & Self-Adhesive

NewsMay.30,2025

-

Contact Paper for Dresser Tops Waterproof, Durable & Easy Install

NewsMay.29,2025