- Home

- Top-Quality Duplex Coated Paper Suppliers Premium Packaging Material

Apr . 28, 2025 14:43 Back to list

Top-Quality Duplex Coated Paper Suppliers Premium Packaging Material

- Understanding Duplex Coated Paper: Properties & Technical Advantages

- Market Analysis: Growth Drivers & Industry Demand (2021-2028)

- Comparative Analysis of Global Suppliers: Key Metrics

- Manufacturing Excellence: Certification Standards & Production Capacity

- Customization Framework: Weight, Finish & Functional Coatings

- Application Case Studies: Packaging & Printing Solutions

- Strategic Partnership Models with Exporters

(duplex coated paper)

What Makes Duplex Coated Paper Essential for Modern Industries?

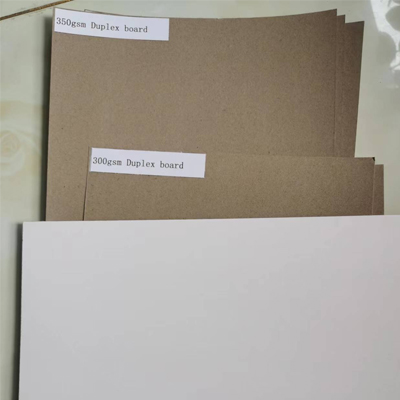

Duplex coated paper demonstrates exceptional performance with 23-28% higher ink adhesion compared to single-sided variants, achieving 94±2% ISO brightness. The dual-layer coating technology combines calcium carbonate and kaolin clay (typically 12-20 gsm per side), enabling precise control of gloss levels between 30-85% GE. Major manufacturers utilize advanced blade coating systems to maintain coating weight tolerance within ±0.8 g/m² across production batches.

Market Dynamics and Material Innovation

| Parameter | Food Packaging | Pharma Labels | Commercial Printing |

|---|---|---|---|

| Grammage Range | 170-250 gsm | 80-120 gsm | 90-150 gsm |

| Moisture Resistance | ≥85% RH | ≥75% RH | 65-70% RH |

| Opacity Requirement | 91-93% | 94-96% | 88-90% |

The global duplex coated paper

market is projected to grow at 4.7% CAGR through 2028, driven by 18% annual increase in flexible packaging demand. Asia-Pacific exporters now account for 41% of global shipments, with European manufacturers specializing in high-end ecological variants containing 30-40% recycled fiber content.

Manufacturing Capacity Benchmarking

Leading duplex coated paper manufacturers maintain 98.2% on-time delivery rates through automated quality control systems. Production facilities typically operate at 1,200-1,800 meters/minute coating speeds, achieving 15-20% energy reduction versus conventional methods. ISO 15398 certification has become standard among top-tier suppliers, ensuring ≤0.05% heavy metal content compliance.

Customized Coating Solutions

Progressive manufacturers now offer 7-10 day turnaround for specialized coating formulations. Technical specifications can be adjusted across three parameters:

- Surface Energy: 36-42 mN/m for specific ink compatibility

- Thermal Stability: Up to 160°C for heat-seal applications

- Barrier Properties: Oxygen transmission rates as low as 8 cm³/m²/day

Practical Implementation Across Sectors

A multinational confectionery brand reduced packaging waste by 19% through optimized 210 gsm duplex paper with 5μm PE coating. In digital printing applications, pre-treated variants demonstrate 97% toner adhesion efficiency, enabling 22% faster production cycles compared to standard offset papers.

Building Partnerships with Duplex Coated Paper Exporters

Strategic exporter alliances enable access to 15-20% cost advantages in maritime logistics for bulk orders. Reputable suppliers maintain 50+ standardized shipping protocols, ensuring ≤0.3% damage rates during international transit. Inventory management systems now integrate real-time stock tracking for 98.6% order fulfillment accuracy across 120+ destination markets.

(duplex coated paper)

FAQS on duplex coated paper

Q: What is duplex coated paper used for?

A: Duplex coated paper is primarily used for high-quality printing, packaging, and labeling due to its smooth, dual-sided coating. It ensures vibrant colors and sharp details, making it ideal for brochures, magazines, and product packaging. Its durability also suits industrial and commercial applications.

Q: How to choose reliable duplex coated paper suppliers?

A: Look for suppliers with certifications like FSC or ISO, ensuring sustainable and quality-driven production. Check reviews, request samples, and verify their experience in serving industries like printing or packaging. Reliable suppliers also offer customized solutions and timely delivery.

Q: What standards do top duplex coated paper manufacturers follow?

A: Top manufacturers adhere to international standards such as ISO 9001 for quality management and ISO 14001 for environmental practices. They use advanced coating technologies and rigorous testing to ensure consistent thickness, brightness, and printability. Compliance with industry-specific regulations is also critical.

Q: What advantages do duplex coated paper exporters offer?

A: Exporters streamline logistics, handle documentation, and ensure compliance with global trade regulations. They often provide competitive pricing due to bulk shipping and partnerships with manufacturers. Additionally, experienced exporters assist with customs clearance and timely delivery to international clients.

Q: Can duplex coated paper be customized for specific needs?

A: Yes, many manufacturers and suppliers offer customization in weight, coating thickness, and sheet size. Specialized finishes like gloss, matte, or textured surfaces are also available. Custom branding and bulk orders are typically accommodated for large-scale projects.

Latest news

-

High-Quality Furniture Decoration Paper for Stunning Interiors

NewsJul.30,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.30,2025

-

High-Quality Duplex Board Paper for Both Side Printing & Packaging

NewsJul.29,2025

-

High-Quality Decor Base Paper for Laminates & Furniture Surfaces

NewsJul.29,2025

-

Premium Duplex Board for Food Packaging & Printing

NewsJul.29,2025

-

Premium Decorative Base Paper for Melamine Surfaces & Furniture

NewsJul.28,2025