- Home

- Premium Duplex Board | Food Packaging & Printing Solutions

Juil . 22, 2025 00:01 Back to list

Premium Duplex Board | Food Packaging & Printing Solutions

Duplex board, a versatile paperboard material, has become essential in modern packaging and printing industries. This laminated paper substrate features two distinct layers bonded together - typically a high-quality top layer and a coarser bottom layer - providing exceptional printability and structural integrity. With increasing demand in food packaging and premium consumer goods, understanding the technical specifications and advancements in duplex board is critical for manufacturers and packaging designers.

XINGTAI SHINEWAY PAPER & DECORATION CO., LTD

Leading manufacturer specializing in duplex board with grey back for international markets:

- 📍 Address: XINGTAI CITY, HEBEI PROVINCE, CHINA

- 📞 Phone: 0319-5914900

- ✉️ Email: 441835323@qq.com

- 🌐 Website: www.shinewaypaper.com

According to the International Corrugated Packaging Association, the global paperboard market is projected to reach $285 billion by 2027, with duplex board accounting for over 25% of food-grade packaging solutions. Technological innovations in coating processes have enabled enhanced moisture resistance and print fidelity, expanding applications across diverse industries.

Technical Specifications of Duplex Board

| Parameter | Range | Standards | Application |

|---|---|---|---|

| Basis Weight (GSM) | 230-450 g/m² | ISO 536 | Light to heavy packaging |

| Caliper (Thickness) | 250-600 μm | TAPPI T411 | Structural rigidity |

| Brightness (Top Layer) | 80-95% ISO | ISO 2470 | Print quality |

| Surface Smoothness | 1.5-3.0 μm | Bendtsen Method | Printability |

| Tensile Strength (MD) | 4.0-10.0 kN/m | ISO 1924 | Packaging durability |

| Stiffness (Bending) | 5-15 mN.m | TAPPI T566 | Structural support |

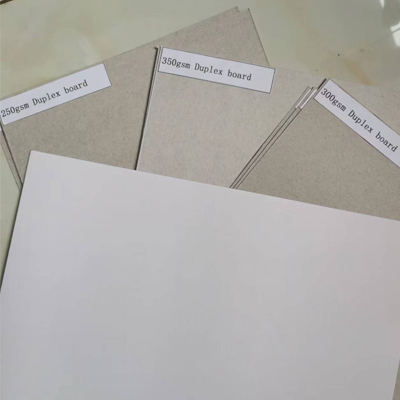

Product Showcase: Duplex Board with Gray Back

Duplex board is widely used in Packing and Printing industrial applications like: shoe box, food box, cake box, and cosmetic packaging. Our duplex board paper comes in white/gray back and white/white back options in both Lightweight Coated (LWC) and Heavyweight Coated (HWC) varieties.

Available Specifications:

- Grammage: 230-450 GSM

- Sizes: 1092*787mm, 1194*889mm, 610*860mm, 31*43"

- Surface Finishes: Machine-glazed, coated, matte

- Backing Options: Gray back or white back

The coated duplex board grey back variant provides excellent color reproduction with minimum 4-color process printing capabilities. Special barrier coatings can be applied for direct food contact, certified to FDA and EU food safety standards.

Industry Applications

Food Packaging Solutions

Duplex board food packaging requires specific barrier properties to protect contents from moisture, grease, and aroma contamination. Our FDA-compliant solutions include:

- Frozen food boxes with moisture-resistant coatings

- Grease-resistant quick-service container111s

- Microwave-safe paperboard trays

- Bakery and confectionery boxes with high crush resistance

Premium Consumer Goods

The superior printability of both side printing photo paper grade duplex board enables high-end applications:

- Luxury cosmetic packaging

- Electronics packaging with static-dissipative properties

- Pharmaceutical blister packaging

- Premium gift boxes with specialty coatings (soft-touch, metallic)

"Advancements in functional barrier coatings have expanded duplex board applications into sectors previously dominated by plastics. The 2025 recyclability targets in Europe will further accelerate this transition." - International Journal of Packaging Research

Professional Technical FAQ

What's the primary difference between duplex board with gray back versus white back?

The gray back variant utilizes recycled fibers in the base layer, offering a cost-effective solution where backside appearance isn't critical. White back uses premium bleached fibers throughout for applications requiring printing on both sides or maximum brightness.

How does grammage affect duplex board performance in packaging?

Higher GSM values (350-450 g/m²) provide superior structural rigidity needed for stacking strength in shipping container111s, while lower GSM (230-300 g/m²) offers flexibility for intricate folding operations in retail packaging.

What coatings are suitable for food-grade duplex board applications?

FDA-compliant barrier coatings include polyethylene extrusion for moisture resistance, EVOH coatings for aroma barrier properties, and fluorochemical treatments for grease resistance in food service applications.

What printing techniques work best on coated duplex board?

Offset lithography delivers the highest image quality for photographic reproduction, while flexographic printing is preferred for large-run packaging. Digital UV printing provides exceptional results for short-run specialty packaging.

How does duplex board compare to solid bleached board (SBB) for premium packaging?

While SBB offers slightly better formation uniformity, modern duplex board achieves comparable print results at 15-20% lower cost while utilizing recycled fiber content.

What international standards govern duplex board food packaging?

Key certifications include FDA 21 CFR 176.170, EU Regulation 1935/2004, BfR XXXVI for Germany, and IS 15495 for India. Migration limits for heavy metals are defined under EN 14338.

How is moisture content managed in duplex board manufacturing?

Optimal moisture content (5.5-7.5%) is maintained through humidity-controlled environments and inline moisture sensors during calendaring to prevent warping and maintain dimensional stability.

Material Innovation & Sustainability

Leading duplex board paper manufacturers are driving sustainability improvements:

- FSC-certified fiber sourcing programs ensuring responsible forestry

- Closed-loop water systems reducing consumption by 45% since 2010

- Bio-based barrier coatings replacing traditional plastics

- Process innovations achieving 30% reduction in energy intensity

The duplex paper stock produced by XINGTAI SHINEWAY contains up to 85% post-consumer recycled content while maintaining print performance through advanced deinking and refining processes. Our grey back variants further conserve resources by optimizing the ratio of virgin to recycled fibers without compromising performance.

"Lifecycle assessments demonstrate that duplex board packaging has 65% lower carbon footprint than equivalent plastic alternatives and offers superior recyclability in existing paper waste streams." - Sustainable Packaging Coalition Report 2024

Market Data & Future Outlook

The global duplex board market shows strong growth projections:

- Asia-Pacific region accounting for 42% of demand growth through 2028

- E-commerce packaging driving 8.2% annual increase in premium duplex board grades

- Food service applications projected to grow at 7.1% CAGR through 2030

- Advanced barrier solutions capturing share in medical packaging segment

"Technical innovations in water-based barrier coatings will enable duplex board to replace an additional 1.2 million tons of plastic packaging by 2027 across food and consumer goods sectors." - Global Packaging Trends Report 2025

Industry References & Citations

- Technical Specifications for Paperboard Packaging - Fibre Box Association: www.fibrebox.org/standards

- Food Safety Standards for Fiber-Based Packaging - European Food Safety Authority: www.efsa.europa.eu/packaging

- Lifecycle Assessment of Packaging Materials - Sustainable Packaging Coalition: www.sustainablepackaging.org/lca

- Global Paperboard Market Analysis 2023-2028 - Smithers Research: www.smithers.com/pulp-paper

For technical specifications sheets, sample requests, or custom duplex board solutions:

Contact XINGTAI SHINEWAY📍 XINGTAI CITY, HEBEI PROVINCE, CHINA | 📞 0319-5914900 | ✉️ 441835323@qq.com

Latest news

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025

-

65gsm ML1085 Paper Specs: Lightweight & Durable for Printing

NewsJul.20,2025

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025