- Home

- Premium Coated Duplex Board Paper | Grey & White Back Options

elo . 23, 2025 02:00 Back to list

Premium Coated Duplex Board Paper | Grey & White Back Options

Understanding Duplex Board Paper: A Core Material in Modern Packaging

In the dynamic world of packaging and printing, the selection of appropriate materials is paramount for both aesthetic appeal and functional integrity. Among the various options available, duplex board paper stands out as a versatile and economical choice. This engineered paperboard, characterized by its multi-layered structure, offers a unique combination of strength, printability, and cost-effectiveness. It is extensively utilized across a multitude of industries, providing robust and visually appealing solutions for consumer and industrial products alike. This article delves into the intricacies of duplex board, exploring its manufacturing, technical specifications, diverse applications, and strategic advantages, aiming to provide B2B decision-makers with comprehensive insights into this indispensable material.

The strategic importance of materials like duplex board cannot be overstated in a market increasingly focused on both sustainability and brand presentation. With its ability to be produced from recycled fibers and its excellent surface for high-quality graphics, it serves as a critical component in achieving packaging objectives that balance environmental responsibility with market demands for attractive and protective solutions. From food packaging to pharmaceutical cartons, the consistent performance of duplex board ensures product safety and enhances consumer perception.

Industry Trends and Market Dynamics

The global market for paperboard, including duplex board, is currently experiencing significant shifts driven by consumer preferences, regulatory changes, and technological advancements. Key trends include a heightened demand for sustainable and recyclable packaging materials, a push towards lighter yet stronger board grades, and the increasing adoption of digital printing technologies. The packaging industry, a primary consumer of duplex board, is witnessing steady growth, particularly in emerging economies, fueled by urbanization and rising disposable incomes.

Sustainability remains a dominant force, with brands actively seeking solutions that reduce environmental impact. This has spurred innovations in the production of coated duplex board with higher recycled content without compromising performance. Furthermore, the rise of e-commerce has amplified the need for durable and protective packaging that can withstand the rigors of shipping, pushing manufacturers to develop boards with enhanced burst strength and stiffness. The shift towards vibrant, high-definition graphics in packaging also necessitates duplex board grades with superior surface smoothness and ink receptivity, such as coated duplex board with grey back or coated duplex board grey back.

According to a report by Grand View Research, the global paperboard packaging market size was valued at USD 170.81 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth underscores the enduring relevance and expanding applications of materials like duplex board in the evolving global economy.

Manufacturing Process of Duplex Board Paper

The production of duplex board paper is a sophisticated process that combines recycled fibers with select virgin pulp to achieve its distinctive multi-layered structure. The manufacturing process is designed to optimize strength, printability, and cost-efficiency. Below are the key stages involved:

1. Raw Material Preparation

- Pulping: Predominantly, recycled paper (e.g., old corrugated container111s, mixed waste paper) forms the bulk of the core layers. These materials are slushed in hydrapulpers to separate fibers, followed by screening and cleaning to remove impurities like plastics, staples, and inks.

- Virgin Pulp: For the top layer (print side) and sometimes the back layer, virgin wood pulp (bleached chemical pulp) is used to ensure superior brightness, smoothness, and print quality. This pulp undergoes separate refining processes to achieve desired fiber characteristics.

2. Stock Preparation

- Refining: Fibers are mechanically treated in refiners to swell them and increase their surface area, enhancing fiber-to-fiber bonding and improving strength properties.

- Additive Introduction: Sizing agents (e.g., rosin, AKD) are added to control water absorption (Cobb value), improving ink holdout and reducing curl. Retention aids, strength enhancers, and optical brighteners are also introduced as needed.

3. Sheet Forming (Multi-ply Process)

Unlike single-ply paper, duplex board is formed in multiple layers, typically on a multi-cylinder machine or a combination of Fourdrinier and cylinder formers. This allows for different pulps to be used for each layer:

- Top Layer: Made from high-quality bleached virgin pulp, often with a white pigment coating, providing excellent printability and brightness.

- Middle/Core Layers: Composed of recycled fibers, providing bulk, stiffness, and cost-effectiveness.

- Back Layer: Can be made from unbleached or lower-grade recycled fibers, resulting in a grey or brown back. This is where products like duplex board grey back or duplex board white back derive their names.

4. Pressing and Drying

The wet sheet passes through a series of press rolls to remove water mechanically, compacting the fibers and increasing sheet density. Following pressing, the board enters a dryer section, typically steam-heated cylinders, to remove remaining moisture. Controlled drying prevents warping and ensures dimensional stability.

5. Surface Treatment and Coating

- Sizing: Surface sizing (e.g., starch) is applied to improve surface strength, reduce dust, and enhance printability.

- Coating: For coated grades, one or more layers of coating (e.g., clay, calcium carbonate, binders) are applied to the top surface. This creates a smooth, bright, and ink-receptive surface crucial for high-quality printing.

6. Calendering and Finishing

The board passes through calender stacks (smooth steel rolls) to compress the sheet, improve smoothness, gloss, and uniform thickness (caliper). Finally, the finished board is wound onto large jumbo reels, then slit into narrower rolls or cut into sheets according to customer specifications.

Quality Control and Testing Standards

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the final product meets stringent industry standards. Key parameters tested include:

- Grammage (GSM): Weight per square meter, tested as per ISO 536 / TAPPI T410.

- Caliper (Thickness): Measured with micrometers as per ISO 534 / TAPPI T411.

- Stiffness: Critical for carton performance, tested using Taber stiffness (ISO 2493 / TAPPI T489) or L&W stiffness testers.

- Burst Strength: Resistance to rupture, tested as per ISO 2758 / TAPPI T403.

- Brightness: Measured using a spectrophotometer (ISO 2470 / TAPPI T452).

- Cobb Value: Water absorption, tested as per ISO 535 / TAPPI T441.

- Surface Smoothness: Evaluated by methods like Bendtsen or Sheffield, crucial for print quality.

These tests ensure the duplex board paper delivers consistent performance, particularly in downstream processes like printing, creasing, folding, and gluing, and provides an estimated service life equivalent to the product it packages, typically ranging from months to several years depending on storage conditions and application.

Technical Specifications and Parameters

The performance and suitability of duplex board for specific applications are defined by a range of technical specifications. These parameters dictate the board's physical properties, printability, and converting characteristics. Understanding these specifications is crucial for purchasers and engineers in selecting the optimal material for their packaging needs.

Key Technical Parameters for Duplex Board

| Parameter | Unit | Typical Range (Coated Duplex Board Grey Back) | Relevant Standard |

|---|---|---|---|

| Grammage (GSM) | g/m² | 180 - 450 | ISO 536 / TAPPI T410 |

| Caliper | µm | 220 - 700 | ISO 534 / TAPPI T411 |

| Stiffness (MD) | mN | 150 - 6000 | ISO 2493 / TAPPI T489 |

| Stiffness (CD) | mN | 80 - 3000 | ISO 2493 / TAPPI T489 |

| Burst Index | kPa·m²/g | 2.0 - 4.5 | ISO 2758 / TAPPI T403 |

| Brightness (Top Side) | % ISO | 80 - 92 | ISO 2470 / TAPPI T452 |

| Surface Roughness (Bendtsen) | ml/min | 50 - 250 | ISO 8791-2 |

| Cobb Value (60s) | g/m² | 20 - 40 | ISO 535 / TAPPI T441 |

| Moisture Content | % | 6 - 8 | ISO 287 / TAPPI T412 |

These specifications are crucial for ensuring that the selected duplex board performs optimally in various processing stages such as cutting, creasing, folding, gluing, and printing. Manufacturers often provide detailed technical data sheets to help customers match the right grade to their specific requirements.

Technical Advantages of Duplex Board Paper

The widespread adoption of duplex board paper across diverse industries is a testament to its multifaceted technical advantages. These benefits contribute significantly to its appeal as a cost-effective, high-performance packaging and printing medium.

- Superior Printability: The coated surface of duplex board provides an exceptionally smooth and bright canvas for high-quality graphics. This allows for vibrant color reproduction, sharp image definition, and excellent ink holdout, critical for effective branding and consumer appeal. Whether using offset, flexo, or gravure printing, duplex board ensures consistent and striking visual results.

- High Stiffness and Strength: Comprising multiple layers, often with a significant proportion of recycled fibers in the core, duplex board offers impressive stiffness-to-weight ratios. This structural integrity is vital for maintaining carton shape, protecting contents during transit, and enabling stable stacking. Its robust nature makes it ideal for packaging items that require physical protection.

- Cost-Effectiveness: The ability to utilize recycled fibers for the inner layers makes duplex board a more economical choice compared to virgin fiber-only alternatives. This cost advantage allows businesses to produce high-quality packaging without incurring prohibitive expenses, making it accessible for a broader range of products.

- Versatility in Application: Available in various grammages and finishes (e.g., gloss, matte, semi-gloss), coated duplex board can be tailored to specific end-use requirements. Its adaptability extends to different converting processes such as die-cutting, creasing, folding, and gluing, ensuring compatibility with standard packaging machinery.

- Dimensional Stability: Proper manufacturing and moisture control ensure that duplex board exhibits good dimensional stability, minimizing issues like curling or warping during storage and printing. This consistency is crucial for efficient high-speed production lines.

- Barrier Properties (with coating options): While inherently a paper-based material, specific coatings can impart enhanced barrier properties against moisture, grease, or oxygen, extending the shelf life of packaged goods, especially for food and pharmaceutical applications.

- Sustainability Aspects: Leveraging recycled content, particularly in grades like duplex board grey back, contributes to resource conservation and reduces landfill waste. Many manufacturers also offer FSC-certified options, ensuring responsible forest management.

These technical merits collectively position duplex board as a preferred material for businesses seeking to balance performance, aesthetics, and economic considerations in their packaging and printing operations.

Application Scenarios and Case Studies

The versatility of duplex board paper makes it indispensable across a vast array of industries. Its blend of visual appeal and structural integrity makes it suitable for packaging solutions that require both brand representation and product protection.

Target Industries and Typical Applications:

- Food & Beverage Packaging: Commonly used for cereal boxes, frozen food cartons, confectionery boxes, tea and coffee packaging, and general food product secondary packaging. The clean surface of coated duplex board is ideal for vibrant food-related graphics.

- Pharmaceutical Packaging: Crucial for medicine boxes, medical device packaging, and healthcare product cartons where clear branding, precise information, and protective enclosure are vital. Grades meeting specific hygiene standards are often utilized.

- Cosmetics & Personal Care: Provides elegant and sturdy packaging for perfume boxes, make-up kits, soap wrappers, and other personal care items, leveraging the smooth surface for premium print finishes.

- Consumer Electronics: Used for packaging mobile phones, small appliances, accessories, and components, where the stiffness of duplex board protects delicate items during handling and transit.

- Textiles & Apparel: For shirt boxes, hosiery packaging, and general garment boxes, offering a balance of protection and sophisticated presentation.

- Toys & Games: Ideal for packaging toy kits, board games, and action figures, providing durable and visually engaging packaging that attracts consumers.

- General Purpose Packaging: Wide use in shoeboxes, detergent boxes, spare parts packaging, and promotional displays where rigidity and print quality are essential.

Application Case Studies:

Case Study 1: Premium Confectionery Packaging

A leading confectionery brand sought to upgrade its chocolate box packaging to convey a more premium image while maintaining cost efficiency. By opting for a 250 GSM coated duplex board white back, they achieved exceptional print results with metallic inks and embossing, which significantly elevated the product's shelf appeal. The board's stiffness provided structural integrity, preventing damage to the delicate chocolates during shipping and retail display. This move resulted in a 15% increase in sales within the first quarter post-launch, demonstrating the power of high-quality packaging.

Figure 1: High-quality printing on duplex board paper for consumer packaging.

Case Study 2: Pharmaceutical Carton Optimization

A pharmaceutical manufacturer faced challenges with inconsistent folding and gluing on their high-speed packaging lines due to variable board quality. Switching to a consistent 300 GSM duplex board grey back from a certified supplier, known for its uniform caliper and stiffness, dramatically improved line efficiency. The enhanced dimensional stability and excellent creasing performance of the new board reduced packaging line stoppages by 20%, leading to significant cost savings in labor and waste. The chosen board also met ISO 9001 quality standards, assuring compliance for sensitive pharmaceutical products.

Vendor Comparison and Selection Criteria

Choosing the right supplier for duplex board is a critical decision that impacts product quality, supply chain efficiency, and overall cost. B2B decision-makers must evaluate vendors based on a comprehensive set of criteria beyond just unit price.

Key Selection Criteria:

- Product Quality Consistency: Assess the vendor's ability to consistently supply duplex board that meets specified grammage, caliper, stiffness, and printability parameters. Requesting sample batches and reviewing quality control reports (e.g., Certificates of Analysis) is essential.

- Certifications and Compliance: Verify relevant industry certifications such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), FSC (Forest Stewardship Council) for sustainable sourcing, and potentially food-grade certifications (e.g., FDA compliance) if applicable for the end product.

- Supply Chain Reliability: Evaluate lead times, production capacity, inventory management, and logistical capabilities. A reliable supply chain minimizes disruption and ensures just-in-time delivery.

- Technical Support and Expertise: A good vendor offers technical assistance, helping clients select the optimal board grade, troubleshoot processing issues, and innovate new packaging solutions. This includes understanding the nuances of coated duplex board grey back versus white back.

- Customization Capabilities: For specialized packaging, the ability to provide custom sizes, grammages, or surface treatments is a significant advantage.

- Pricing Structure and Payment Terms: While not the sole factor, competitive pricing coupled with favorable payment terms can greatly influence the total cost of ownership.

- Environmental Practices: In line with sustainability trends, consider vendors with strong environmental commitments, including efficient resource use, waste reduction, and responsible sourcing.

Comparison Table: Key Duplex Board Grades

| Feature | Coated Duplex Board Grey Back | Coated Duplex Board White Back |

|---|---|---|

| Back Surface Color | Grey/Brown | White |

| Primary Use | General packaging, industrial use, cost-sensitive applications | Premium packaging, pharmaceutical, cosmetics, high-end consumer goods |

| Printability (Back) | Limited or none (suited for hidden areas) | Good, suitable for internal printing, instructions, or branding |

| Cost-Effectiveness | Higher | Moderate |

| Recycled Content | Often higher | Can vary, often includes virgin pulp for whiteness |

By carefully considering these factors and comparing different grades of duplex board, businesses can forge strong, long-term partnerships with suppliers that align with their strategic objectives.

Customized Solutions and Innovations

The evolving demands of modern markets frequently necessitate packaging solutions that go beyond standard offerings. Leading manufacturers of duplex board understand this need and invest in R&D to provide customized solutions and innovative product features.

- Tailored Grammage and Caliper: While standard ranges exist, specific applications may require a unique balance of stiffness and bulk. Custom grammage and caliper options allow for optimization of packaging weight, material usage, and protective capabilities.

- Specialized Coatings: Beyond standard clay coatings, innovations include barrier coatings for moisture, grease, or oxygen resistance, heat-sealable coatings for direct food contact, and soft-touch coatings for a premium tactile experience.

- Enhanced Surface Treatments: Options for higher gloss, matte finishes, or improved ink adhesion for specific printing technologies (e.g., UV printing) can be developed to meet precise brand requirements. For instance, some coated duplex board with grey back can be treated for enhanced printability on its primary side.

- Sustainable Formulations: Manufacturers are increasingly offering grades with higher percentages of recycled content, alternative fiber sources, or biodegradable coatings to align with corporate sustainability goals and consumer preferences for eco-friendly packaging.

- Anti-Counterfeiting Features: Integrating features like watermarks or micro-perforations during manufacturing can add a layer of security to high-value product packaging.

Collaborating with suppliers who offer these customization capabilities ensures that businesses can develop truly differentiated and optimized packaging solutions that resonate with their brand identity and operational needs.

Product Spotlight: Duplex Board with Brown Back

Shineway Paper offers a specialized grade of duplex board known as "Duplex Board with Brown Back". This product is specifically engineered to provide an optimal balance of robust performance and cost-effectiveness, making it a popular choice for a wide range of packaging applications where the back surface is not visible or requires a more natural, uncoated appearance.

Key Characteristics:

- Coated White Top: The printing surface is coated, ensuring excellent brightness, smoothness, and ink receptivity for high-quality graphics and brand messaging.

- Uncoated Brown Back: The reverse side features an uncoated brown finish, which is economical and often preferred for internal packaging, hidden areas of a carton, or where a more rustic look is desired. This allows for significant cost savings compared to double-coated or white-back options.

- High Stiffness: Built with multiple layers of recycled fiber, it delivers superior stiffness and structural integrity, ensuring cartons maintain their shape and protect contents effectively.

- Versatile Grammage Range: Available in a comprehensive range of grammages to suit various packaging needs, from lighter cartons to heavy-duty boxes.

- Environmentally Conscious: Utilizes a high percentage of recycled content, aligning with sustainable packaging initiatives.

Ideal Applications:

This specific grade is particularly well-suited for:

- General consumer product packaging (e.g., detergents, soaps, household items)

- Food packaging (outer cartons for dry goods, cereals, frozen foods)

- Toy and game packaging

- Industrial packaging and displays

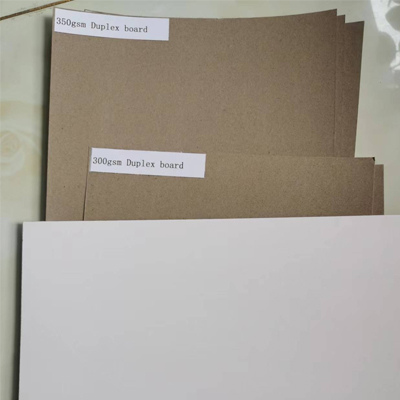

Figure 2: Duplex board paper exhibiting its distinct brown back.

Customer Feedback and Testimonials

At Shineway Paper, our commitment to quality and customer satisfaction is reflected in the positive feedback we receive from our partners. Our duplex board solutions are trusted by leading brands across various sectors.

"We've been sourcing Shineway's Duplex Board with Brown Back for our confectionery packaging for over five years. The consistency in quality, especially the print surface, is exceptional. It allows our designs to really pop, and the board's stiffness ensures our product arrives in perfect condition. Their technical support team has also been invaluable in helping us optimize our printing process."

"For our pharmaceutical cartons, compliance and reliability are non-negotiable. Shineway's duplex board meets all our stringent requirements, including ISO certifications. Their lead times are dependable, which is crucial for our production planning. The uniform caliper has significantly reduced our waste on automated packaging lines."

Certifications & Quality Assurance

Shineway Paper maintains a steadfast commitment to quality and environmental stewardship. Our manufacturing processes and products, including our range of duplex board, adhere to internationally recognized standards and certifications, providing our clients with assurance and trust.

- ISO 9001:2015 Certified: Our Quality Management System ensures consistent product quality and continuous improvement across all operations, from raw material sourcing to final product delivery.

- ISO 14001:2015 Certified: Demonstrates our dedication to environmental management, minimizing our ecological footprint through sustainable practices, responsible resource usage, and waste reduction.

- FSC® (Forest Stewardship Council) Certified: Available upon request, our FSC-certified duplex board guarantees that the virgin wood fiber used originates from responsibly managed forests, promoting sustainable forestry.

- RoHS & REACH Compliance: Our products are tested to comply with Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) directives, ensuring they are safe for consumers and the environment.

- Extensive In-house Testing: Beyond external certifications, every batch of duplex board undergoes rigorous in-house testing for key parameters such as grammage, caliper, stiffness, burst strength, and printability, utilizing advanced laboratory equipment and following TAPPI and ISO test methods.

Our long-standing relationships with global partners and over two decades of industry experience further underscore our authoritative position as a reliable supplier of high-quality paperboard solutions.

Trustworthiness Module

Lead Time and Fulfillment

We understand the critical importance of timely delivery in today's fast-paced supply chains. Our standard lead time for most duplex board orders is 15-20 business days from order confirmation, subject to current production schedules and material availability. For urgent requirements or large-volume projects, we offer expedited production options. Our robust logistics network ensures efficient and reliable delivery to global destinations, with comprehensive tracking available for all shipments. We prioritize clear communication throughout the fulfillment process, providing regular updates to our clients.

Warranty Commitments

Shineway Paper stands behind the quality of its products. All our duplex board is manufactured to meet or exceed industry standards and specified technical parameters. We offer a warranty guaranteeing that our products will be free from material defects and conform to agreed-upon specifications at the time of delivery. In the rare event of a quality discrepancy, we are committed to promptly investigating and resolving the issue, including replacement of materials or credit, in accordance with our terms and conditions.

Customer Support and After-Sales Service

Our commitment to our clients extends far beyond the point of sale. Shineway Paper provides comprehensive customer support and after-sales service designed to ensure your complete satisfaction. Our dedicated team of technical experts and customer service representatives are available to assist with:

- Technical inquiries and product selection guidance.

- Troubleshooting printing or converting issues.

- Order tracking and logistics support.

- Handling feedback and quality concerns.

We believe in building long-term partnerships through responsiveness, expertise, and proactive support. Our goal is to ensure seamless integration of our duplex board into your operations.

Frequently Asked Questions (FAQ)

- Q1: What is the primary difference between coated duplex board grey back and white back?

- A1: The primary difference lies in the appearance and composition of the back layer. Coated duplex board grey back has an uncoated grey or brown reverse side, typically made from recycled fibers, offering a more economical option. Coated duplex board white back has a bleached, coated, or semi-coated white reverse side, often from virgin pulp or high-grade recycled pulp, making it suitable for applications where both sides of the board are visible or require printing.

- Q2: Can duplex board be used for food packaging?

- A2: Yes, certain grades of duplex board are suitable for food packaging, particularly for secondary packaging or for direct food contact when treated with appropriate food-safe coatings or laminations. It's crucial to select grades that comply with relevant food contact regulations (e.g., FDA, BfR) and to verify certifications from the supplier.

- Q3: What are the typical grammage ranges available for duplex board paper?

- A3: Duplex board paper is commonly available in a wide range of grammages, typically from 180 GSM (Grams per Square Meter) up to 450 GSM or even higher. The specific grammage selected depends on the required stiffness, bulk, and application, from lightweight cartons to sturdy boxes.

- Q4: Is duplex board considered an environmentally friendly option?

- A4: Yes, duplex board is often considered an environmentally friendly option due to its high recycled content, particularly in grades with a grey or brown back. Many manufacturers also offer FSC-certified products, ensuring responsible sourcing of virgin fibers, and the material is generally recyclable, contributing to a circular economy.

- Q5: How does the stiffness of duplex board impact its performance?

- A5: Stiffness is a critical parameter for duplex board. High stiffness ensures cartons maintain their structural integrity, resist crushing during stacking and transport, and perform well on high-speed packaging lines. It prevents unwanted deformation (e.g., bulging or sagging) and contributes to the overall protective quality of the packaging. Stiffness is measured in both Machine Direction (MD) and Cross Direction (CD) and is typically specified according to ISO or TAPPI standards.

Conclusion

Duplex board paper remains a cornerstone of the packaging and printing industry, offering an unparalleled blend of versatility, printability, strength, and cost-effectiveness. Its multi-layered construction, combined with advanced manufacturing processes and stringent quality control, enables it to meet the diverse and evolving demands of global markets. From enhancing brand aesthetics to ensuring product protection and aligning with sustainability goals, duplex board provides a robust solution for a myriad of applications. As industries continue to innovate, the adaptability and continuous improvement in duplex board manufacturing will ensure its enduring relevance as a preferred material for B2B applications worldwide. Partnering with a reputable and technically proficient supplier is key to harnessing the full potential of this essential paperboard.

References

- Grand View Research. (2023). Paperboard Packaging Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/paperboard-packaging-market

- TAPPI Technical Information Papers. (Various). Standard test methods for paper, paperboard, and pulp. Retrieved from https://www.tappi.org/

- ISO - International Organization for Standardization. (Various). Standards for paper, board and pulps. Retrieved from https://www.iso.org/standards.html

- Forest Stewardship Council (FSC). (2024). About FSC. Retrieved from https://fsc.org/en/about-fsc

- Food and Drug Administration (FDA). (Various). Regulations for Food Packaging. Retrieved from https://www.fda.gov/food/packaging-food-contact-substances-fcs/packaging-food-contact-substances

Latest news

-

Premium Coated Duplex Board Paper | Grey & White Back Options

NewsAug.23,2025

-

Premium Decorative Base Paper for Stylish Laminates & Panels

NewsAug.22,2025

-

Premium Decor Base Paper for Furniture & Laminates

NewsAug.21,2025

-

Easy Self Adhesive Paper for Wooden Furniture Decor

NewsAug.19,2025

-

Premium Decor Base Paper: High-Quality Melamine Impregnated Paper

NewsAug.18,2025

-

High-Quality Duplex Board for Packaging & Printing

NewsAug.17,2025