- Home

- High-Quality Duplex Board for Packaging & Printing

Abu . 17, 2025 01:20 Back to list

High-Quality Duplex Board for Packaging & Printing

Understanding Duplex Board in the Modern Packaging Landscape

In the rapidly evolving global packaging industry, the demand for versatile, high-performance, and sustainable materials is at an all-time high. Among the plethora of options, duplex board stands out as a foundational material, especially the variant with a gray back, which has carved a significant niche due to its exceptional printability, rigidity, and cost-effectiveness. This material, often referred to as duplex board paper, is engineered for a wide array of applications, from consumer goods packaging to intricate printing projects. The current industry trends highlight a sustained growth in demand for such paperboard solutions, driven by factors like the burgeoning e-commerce sector, increased awareness regarding eco-friendly packaging alternatives, and the continuous innovation in printing technologies that necessitate superior surface finishes. Manufacturers are constantly innovating to produce duplex board that not only meets stringent quality standards but also offers enhanced features like improved moisture resistance, higher bulk, and superior smoothness for both side printing photo paper quality. This includes focusing on environmental sustainability through recycled content and efficient production processes. The versatility of duplex board with grey back makes it an indispensable choice for brands seeking a balance between premium presentation and economic viability. Its inherent strength and adaptability ensure that products are not only protected during transit and storage but also presented in an aesthetically appealing manner, crucial for brand recognition and consumer engagement in a competitive market.

The technical prowess of duplex board lies in its multi-layered construction, typically featuring a coated white surface on one side for superior printing results and a gray back made from recycled fibers, offering strength and stability. This composite structure is meticulously engineered to provide optimal stiffness, foldability, and surface smoothness, crucial parameters for high-speed printing and automated packaging lines. Beyond its foundational use in general packaging, specialized applications like duplex board food packaging require adherence to stringent food-grade safety standards, often involving specific barrier coatings or virgin fiber layers to prevent contamination and preserve product integrity. The market for coated duplex board grey back is experiencing robust growth, propelled by the food and pharmaceutical sectors' need for durable, hygienic, and printable packaging solutions. Furthermore, advancements in manufacturing technologies allow for custom tailored properties, such as enhanced brightness levels, increased tear resistance, or specific caliper tolerances, making it possible for manufacturers to meet highly specific client requirements. This adaptability ensures that whether the end product is a high-end cosmetic box or a robust electronics package, the duplex board can be optimized to deliver peak performance. The ongoing research and development in this sector also focus on reducing the environmental footprint of production, through optimizing water and energy consumption, and increasing the use of sustainably sourced raw materials, aligning with global efforts towards a circular economy.

The Manufacturing Process: From Pulp to Premium Board

The production of duplex board with gray back is a sophisticated multi-stage process that begins with the careful selection and preparation of raw materials, primarily wood pulp (virgin or recycled) and various additives. The core of the board, the gray back, is predominantly made from recycled paper fibers, which are pulped and refined to achieve the desired consistency and strength. This process involves breaking down the fibers in water, followed by mechanical and chemical treatments to remove impurities and prepare the slurry. Concurrently, the top layer, which demands superior printability and aesthetic appeal, is typically manufactured from virgin pulp, ensuring high brightness and smoothness. These distinct pulp slurries are then fed into a multi-ply paper machine. Here, the various layers are formed, pressed, and dried sequentially. The initial forming involves depositing the pulp onto wire meshes, allowing water to drain and fibers to interlock. Subsequent pressing stages remove more water and compact the sheets, significantly increasing their density and strength. Drying, often conducted over heated rollers, removes remaining moisture to achieve the final desired moisture content, critical for dimensional stability and preventing warping.

Illustrative image showcasing the various stages of duplex board production, emphasizing material flow and layering.

Following the basic sheet formation and drying, the coated duplex board grey back undergoes critical finishing processes. The top white layer receives a specialized coating, often a blend of pigments, binders, and additives, applied through advanced coating units. This coating enhances printability by providing a smoother, more uniform surface that absorbs ink evenly, resulting in sharper images and vibrant colors. Depending on the specific application, multiple coating layers might be applied. After coating, the board passes through calenders – a series of smooth, heavy rollers – which compress and polish the surface, further improving smoothness, gloss, and caliper consistency. This calendering process is vital for achieving the desired thickness and surface finish, impacting the board's stiffness and overall tactile quality. Quality control is integrated throughout the entire manufacturing process, with continuous monitoring of key parameters such as GSM (grams per square meter), caliper (thickness), brightness, stiffness, and moisture content. Conformance to international standards like ISO 9001 for quality management and ISO 14001 for environmental management is paramount, ensuring product consistency and reliability. The finished jumbo rolls of duplex paper stock are then precisely cut into smaller rolls or sheets according to client specifications, ready for distribution to diverse industries. This rigorous process ensures that the final product offers superior performance in its intended applications, from robust food packaging to high-resolution printing, exhibiting advantages such as excellent anti-corrosion properties (through appropriate barrier coatings for food items) and optimized material usage for energy efficiency in packaging production.

Technical Parameters and Performance Benchmarks

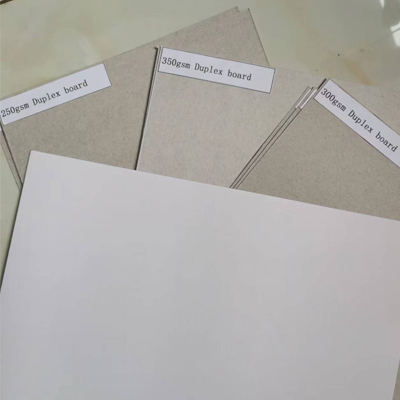

The performance of duplex board is defined by a range of critical technical parameters that directly influence its suitability for various applications. Understanding these specifications is essential for B2B decision-makers to select the appropriate grade for their specific needs. Grammage (GSM), measured in grams per square meter, is a primary indicator of the paperboard's substance and density; typical ranges for duplex board paper are from 200 GSM to 450 GSM, with higher GSM indicating a heavier and often stiffer board. Caliper, or thickness, expressed in micrometers (µm) or points (pt), is equally crucial, directly correlating with the board's bulk and stiffness. For instance, a common 250 GSM duplex board might have a caliper of around 350-400 µm, influencing its runnability on packaging lines and its perceived quality. Stiffness, measured in milliNewtons (mN) or Gurley Stiffness units, quantifies the board's resistance to bending, a vital property for structural integrity in packaging. A higher stiffness value ensures that the packaging maintains its shape and protects the contents effectively. Brightness, usually measured against a blue light source and expressed as a percentage (e.g., 85-92% ISO brightness), indicates the whiteness of the coated surface, which significantly impacts the vibrancy and accuracy of printed colors, a key consideration for both side printing photo paper applications.

Beyond these fundamental parameters, other technical specifications enhance the utility of duplex board. Moisture content, typically maintained between 6-9%, is crucial for dimensional stability and preventing warping, especially in environments with fluctuating humidity. Deviations can lead to print registration issues or poor machine performance. Surface smoothness, measured by methods like Bendtsen or Sheffield, quantifies the uniformity of the board's surface, which directly affects ink absorption and the fidelity of fine print details. A smoother surface results in sharper images and less dot gain during printing. Cobb value, indicating water absorption, is particularly relevant for duplex board food packaging where moisture barrier properties are critical. A lower Cobb value signifies higher resistance to water penetration, important for preserving product freshness and preventing moisture damage. Tear strength, tensile strength, and bursting strength are mechanical properties that ensure the board can withstand handling and stress during packaging and distribution. Reputable duplex board paper manufacturers provide detailed technical data sheets for each product grade, often backed by certifications such as ISO 9001 for quality management and potentially FDA compliance for food contact grades, ensuring that their products meet global benchmarks for performance and safety. These rigorous tests and certifications provide B2B clients with the assurance of consistent quality and reliable performance, critical for maintaining efficiency and product integrity throughout their supply chains.

Typical Technical Specifications of Duplex Board (Coated Grey Back)

| Property | Unit | Typical Range | Test Standard |

|---|---|---|---|

| Grammage (GSM) | g/m² | 200 - 450 | ISO 536 |

| Caliper (Thickness) | µm (microns) | 250 - 650 | ISO 534 |

| Stiffness (MD) | mN | 150 - 1500 | ISO 2493 |

| Stiffness (CD) | mN | 70 - 750 | ISO 2493 |

| Brightness (ISO) | % | 85 - 92 | ISO 2470 |

| Moisture Content | % | 6 - 9 | ISO 287 |

| Surface Smoothness | ml/min (Bendtsen) | 10 - 250 | ISO 8791-2 |

| Cobb Value (60s) | g/m² | 25 - 40 | ISO 535 |

Applications and Customization: Tailoring Duplex Board for Diverse Needs

The inherent versatility of duplex board with grey back makes it a preferred choice across numerous industries for a vast array of applications. Its robust structure and superior printing surface position it as an ideal material for consumer goods packaging, including pharmaceutical products, cosmetics, electronics, and food items. In the pharmaceutical sector, the rigidity and print fidelity of duplex board ensure accurate labeling and protection of sensitive medications, often requiring compliance with specific packaging regulations like those from the FDA for direct food contact or child-resistant features. For the electronics industry, it provides sturdy and customizable boxes for mobile phones, accessories, and small appliances, offering both protection and a professional presentation. The fashion and apparel industry utilizes it for shoe boxes, garment packaging, and accessories, where its ability to convey brand aesthetics through high-quality printing is paramount. Beyond packaging, duplex board paper is extensively used in various printing applications such as book covers, file folders, display stands, calendars, and greeting cards, where its flatness and stiffness contribute to durable and visually appealing end products. The capability for both side printing photo paper quality further expands its utility for promotional materials and artistic prints demanding exceptional clarity and color reproduction on a rigid substrate.

An example of how duplex board is transformed into functional and appealing packaging solutions for various products.

Recognizing the diverse requirements of different industries, leading duplex board paper manufacturers offer extensive customization options, allowing clients to tailor the product precisely to their operational and branding needs. This includes variations in grammage and caliper, enabling optimization for specific package sizes, weight capacities, and machine runnability. Customization extends to surface treatments, where specialized coatings can be applied to enhance moisture resistance (critical for duplex board food packaging or products exposed to humidity), grease barriers, or UV resistance for prolonged shelf life and product integrity. Different levels of brightness and surface smoothness can also be achieved to match desired print quality and aesthetic appeal, from matte finishes for understated elegance to high-gloss surfaces for vibrant visual impact. Furthermore, options for recycled content vary, allowing clients to meet their sustainability targets without compromising on performance. Manufacturers like Shineway Paper provide comprehensive consultation services, leveraging years of expertise to recommend optimal specifications and custom solutions. This collaborative approach ensures that the chosen duplex paper stock not only meets technical performance criteria but also aligns with corporate sustainability goals and budget considerations, delivering maximum value and efficiency for B2B operations. The ability to customize also includes specific roll widths or sheet sizes, minimizing waste and optimizing the cutting and converting processes for clients.

Manufacturer Comparison and Strategic Partnerships

Choosing the right duplex board paper manufacturers is a strategic decision that profoundly impacts product quality, supply chain efficiency, and overall business success for B2B clients. While many manufacturers offer duplex board with gray back, key differentiators lie in their consistency of quality, production capabilities, commitment to sustainability, and customer support. Leading manufacturers typically boast state-of-the-art production facilities, employing advanced process control systems to ensure uniformity across batches. This consistency is vital for high-volume automated packaging lines where even minor variations in caliper or stiffness can lead to costly operational disruptions. Furthermore, reputable suppliers often hold international certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and potentially FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) for sustainable forestry practices, validating their commitment to responsible production. Their technical support teams provide invaluable expertise, assisting clients with material selection, troubleshooting, and optimizing their packaging processes. Client feedback consistently highlights the importance of reliable supply chains, on-time delivery, and responsive technical assistance, particularly for industries with tight production schedules or evolving material requirements.

When evaluating duplex board paper manufacturers, prospective clients should consider several crucial factors beyond just pricing. The breadth of their product portfolio, including various GSMs, calipers, and specialized coatings (e.g., for duplex board food packaging), indicates their capacity to meet diverse needs. Their R&D capabilities are also indicative of their potential for future innovation and adaptation to emerging market trends, such as enhanced recyclability or new barrier properties. For instance, a manufacturer with strong R&D might offer solutions for both side printing photo paper with superior color gamut. Service tenure in the industry, significant partnerships with large-scale converting companies, and a strong track record of successful case studies involving complex packaging challenges further solidify a manufacturer's authority and trustworthiness. Companies that invest in robust quality control systems, from raw material sourcing to final product inspection, consistently deliver superior coated duplex board grey back. Finally, the ability to provide flexible delivery schedules and comprehensive after-sales support, including handling any quality claims efficiently, distinguishes a truly reliable partner. Forming long-term strategic partnerships with such manufacturers can lead to significant operational efficiencies, cost savings, and enhanced product quality, ultimately strengthening the client's competitive position in the market.

Manufacturer Comparison Factors

| Feature | Key Consideration for B2B | Impact on Business |

|---|---|---|

| Quality Consistency | Adherence to specified GSM, caliper, brightness. | Reduces production downtime, ensures consistent product presentation. |

| Certifications (ISO, FDA, FSC) | Proof of quality, environmental, and safety standards. | Enhances brand reputation, facilitates regulatory compliance, market access. |

| Product Customization | Ability to tailor GSM, coatings, sizes for unique needs. | Optimizes material usage, supports specialized packaging designs. |

| Supply Chain Reliability | On-time delivery, inventory management support. | Ensures continuous production, minimizes stockouts. |

| Technical Support | Expert advice, troubleshooting, process optimization. | Resolves issues quickly, improves operational efficiency. |

Frequently Asked Questions (FAQ) about Duplex Board

Q1: What are the primary advantages of using duplex board over other paperboards?

Duplex board offers a unique combination of advantages that make it highly appealing for packaging and printing applications. Its multi-layered structure, particularly the duplex board with gray back, provides excellent rigidity and burst strength, ensuring product protection during handling and transit. The coated white surface allows for superior printability, enabling vibrant colors, sharp images, and intricate designs, which is crucial for brand appeal and consumer engagement. Furthermore, it is generally more cost-effective than virgin fiber boards of similar performance, making it an economically viable option for high-volume production. Its good folding endurance and smooth surface also contribute to efficient processing on automated packaging lines, minimizing waste and maximizing throughput. The use of recycled fibers in the gray back also positions it as a more environmentally conscious choice, aligning with corporate sustainability initiatives.

Q2: Can duplex board be used for food packaging, and what certifications are required?

Yes, duplex board is widely used for duplex board food packaging, particularly for dry or non-direct food contact items like cereal boxes, biscuit packets, and frozen food packaging. For applications involving direct food contact, specialized grades of duplex board are manufactured with virgin fiber layers on the inside and often include specific food-grade barrier coatings (e.g., PE coating for moisture resistance) to ensure product safety and prevent migration of non-food components. Key certifications and compliance standards required for duplex board food packaging typically include FDA (Food and Drug Administration) regulations in the United States, EU food contact material regulations (e.g., EC No 1935/2004), and other national food safety standards. Manufacturers will provide documentation and certificates of compliance to assure safety and suitability for food-related applications.

Q3: What factors should I consider when specifying GSM and caliper for duplex board paper?

Specifying the correct GSM (grammage) and caliper (thickness) for duplex board paper is crucial for optimizing both cost and performance. The primary considerations include the weight and fragility of the product to be packaged, as heavier or more delicate items require higher GSM and caliper for increased rigidity and protection. The desired aesthetic and tactile feel of the final package also play a role; thicker boards often convey a sense of premium quality. Furthermore, the converting process and printing machinery capabilities are vital; certain machines may have limitations on the maximum or minimum thickness they can handle efficiently. For applications requiring both side printing photo paper quality, a balance between print surface quality and necessary rigidity must be achieved. Consult with your duplex board paper manufacturers or suppliers, like Shineway Paper, who can provide expert guidance based on your specific application, product characteristics, and converting equipment.

Q4: What is the typical delivery cycle for custom orders of duplex board?

The typical delivery cycle for custom orders of duplex board can vary significantly depending on several factors, including the order volume, specific customization requirements (e.g., unique GSM, special coatings, custom sizes), the manufacturer's current production schedule, and logistical arrangements. For standard grades and sizes available in stock, lead times might be as short as 1-2 weeks. However, for highly customized orders, especially those requiring specific manufacturing runs or specialized raw materials, the lead time can extend to 4-6 weeks or even longer. Reputable duplex board paper manufacturers will provide a clear and accurate lead time estimate at the time of order confirmation. It is always advisable to communicate your deadlines and supply chain requirements upfront to your supplier to ensure timely delivery and to explore options for expedited shipping if urgent needs arise. Establishing a long-term relationship with a manufacturer can also lead to more favorable and predictable delivery schedules.

Q5: What kind of quality assurance and warranty do duplex board manufacturers provide?

Leading duplex board paper manufacturers implement rigorous quality assurance protocols throughout their production process, from raw material inspection to final product testing. This includes continuous monitoring of key parameters like GSM, caliper, stiffness, brightness, and moisture content, often adhering to international standards such as ISO 9001. A comprehensive quality management system ensures consistency and traceability. Regarding warranty, manufacturers typically guarantee that their duplex board with grey back will meet the agreed-upon technical specifications and be free from manufacturing defects for a specified period from the date of shipment or as per industry norms. In the event of non-conformance, a reliable manufacturer will have a clear process for investigation, claim resolution, and, if necessary, replacement or credit. Always clarify the specific warranty terms and conditions with your chosen supplier to understand their commitment to product quality and post-sales support. Customer support is typically available via phone or email for any technical inquiries or issues.

Authoritative References

- Hubbe, M. A., & Gill, R. A. (2016). Pulp and Paper Chemistry and Technology. TAPPI Press.

- Biermann, C. J. (2009). Handbook of Pulping and Papermaking (3rd ed.). Academic Press.

- Casey, J. P. (1983). Pulp and Paper: Chemistry and Chemical Technology. Wiley.

- ISO (International Organization for Standardization) Standards for Paper, Board and Pulps.

- FDA (U.S. Food and Drug Administration) Regulations for Food Contact Materials.

Latest news

-

High-Quality Duplex Board for Packaging & Printing

NewsAug.17,2025

-

Coated Duplex Board Paper | Double-Sided for Print & Pack

NewsAug.16,2025

-

High-Quality Decor Base Paper for Durable Surface Designs

NewsAug.15,2025

-

High-Quality Decor Base Paper for Furniture & Flooring Laminates

NewsAug.14,2025

-

Premium Decor Base Paper for Laminates & Furniture

NewsAug.13,2025

-

Premium Decor Base Paper for Durable Laminate Surfaces

NewsAug.12,2025