- Home

- OEM Duplex Paper Manufacturing Process - Efficient and Sustainable Solutions

Σεπ . 12, 2024 11:54 Back to list

OEM Duplex Paper Manufacturing Process - Efficient and Sustainable Solutions

The Manufacturing Process of OEM Duplex Paper

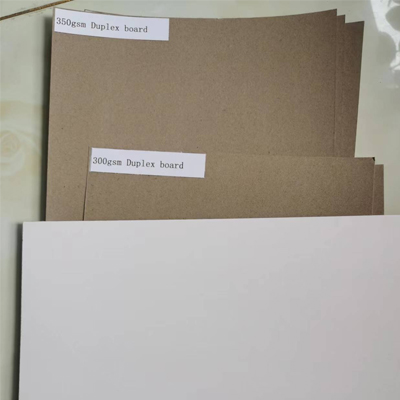

Duplex paper is a type of cardboard that is widely used for packaging and printing applications. It is known for its durability and versatility, making it a popular choice among manufacturers. The production of OEM (Original Equipment Manufacturer) duplex paper involves several key steps, each critical to ensuring high quality and consistency in the final product.

The manufacturing process begins with the selection of raw materials. The primary components for duplex paper production include waste paper, wood pulp, and additives. The choice of raw materials significantly impacts the paper's properties, such as brightness, stiffness, and printability. Recycling waste paper not only reduces environmental impact but also helps in lowering production costs.

Once the raw materials are gathered, they are fed into a pulping machine where they undergo a mechanical and chemical process to break them down into a slurry. This pulp is then cleaned and refined to remove impurities and ensure a uniform consistency. After refining, the pulp is diluted with water to create a pulp mixture, which is necessary for the sheet formation process.

oem duplex paper manufacturing process

The diluted pulp is then spread onto a continuously moving screen known as the Fourdrinier wire. As water continues to drain away, the fibers begin to bond together, forming a wet sheet of paper. This sheet is then pressed between rollers to remove excess water and increase its density. Following this, the paper moves through a series of drying cylinders where hot air is used to remove the remaining moisture, resulting in a dry sheet of duplex paper.

After drying, the duplex paper is coated on one or both sides with a layer of clay or other coatings to enhance printability and improve surface smoothness

. This step is crucial, especially for OEM applications where precise printing is required for branding and packaging purposes.Finally, the finished product is wound into large rolls or cut into sheets according to customer specifications. Quality control is essential throughout the manufacturing process, involving tests for thickness, weight, brightness, and tensile strength to ensure that the duplex paper meets industry standards.

In conclusion, the manufacturing of OEM duplex paper is a complex process that combines technology, raw material selection, and quality control. Its end product serves a vital role in various industries, particularly where high-quality packaging and printing are essential.

Latest news

-

Premium Duplex Board for AI with GPT-4-Turbo

NewsJul.31,2025

-

Premium Decor Base Paper | Durable & Versatile Prints

NewsJul.31,2025

-

High-Quality Furniture Decoration Paper for Stunning Interiors

NewsJul.30,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.30,2025

-

High-Quality Duplex Board Paper for Both Side Printing & Packaging

NewsJul.29,2025

-

High-Quality Decor Base Paper for Laminates & Furniture Surfaces

NewsJul.29,2025