Nyheder

-

What’s the difference between ivory board and duplex board? Duplex Board

Duplex board is made of top pulp and bottom pulp. Its structure is mainly divided into the bottom layer, core layer, lining layer, surface layer and coating layer.Read more -

WHITE BACK DUPLEX BOARD? DO YOU REALLY NEED IT? Duplex Board

Duplex board is a type of paperboard or cardboard, the outside of the board is coated to make it more moisture resistant and reflective, but still uncoated duplex board is sturdy enough to make disposable items.Read more -

What is Duplex Board Paper Manufacturing Process Duplex Board

The coated surface of duplex board paper has high whiteness, smoothness, ink absorption and printing gloss. At the same time, the duplex board paper itself has good stiffness and folding endurance, widely used in paperware, packaging, printing fields. What is duplex board paper manufacturing process?Read more -

4 Types of Paperboard Duplex Board

Our industry lives and breathes paperboard. The thick paper substrate can be transformed into any number of designs, from simple tuck cartons to intricate, sculpted packages that impart a sense of luxury and wonder.Read more -

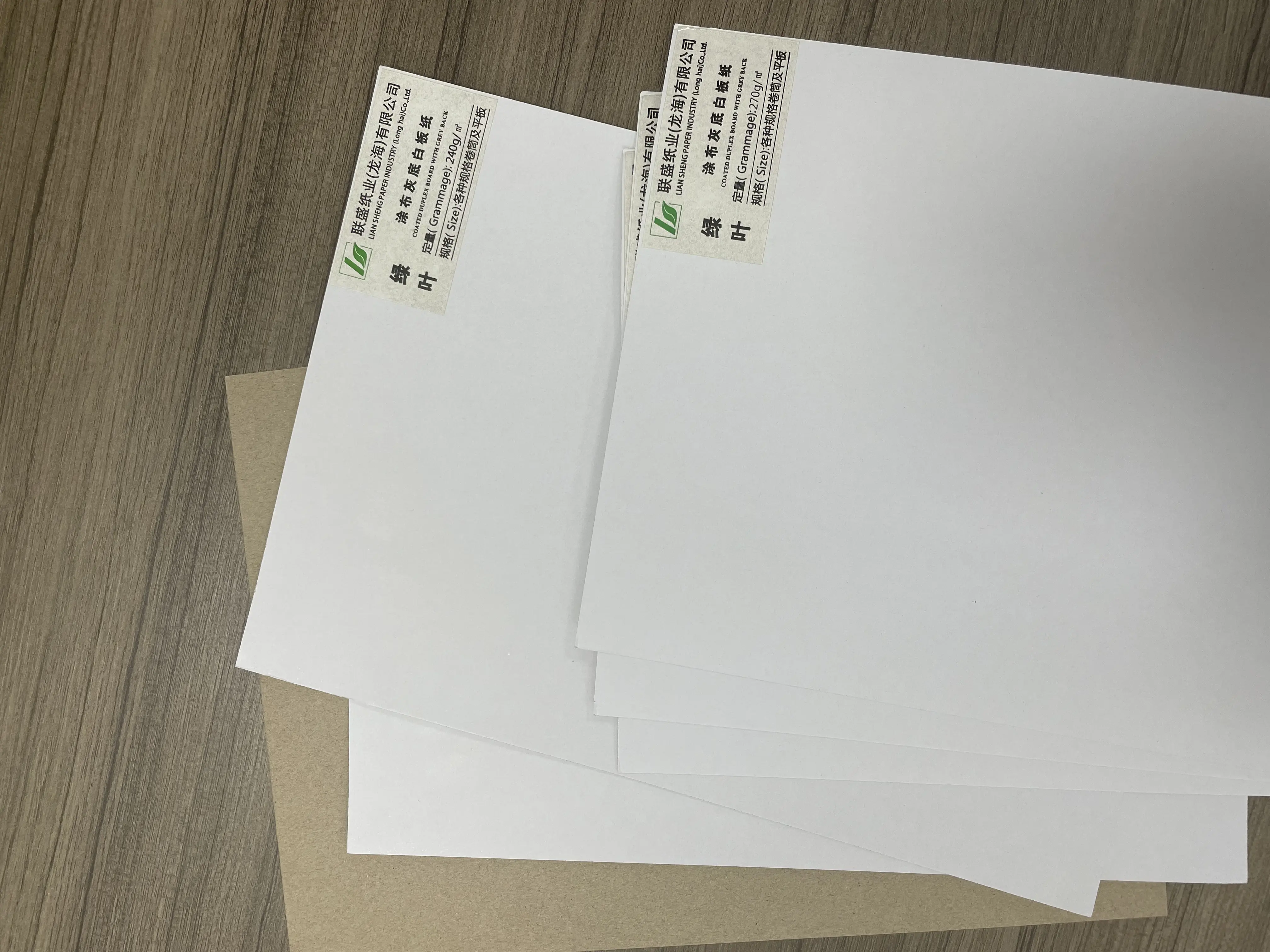

BEST QUALITY GREY & WHITE BACK DUPLEX BOARDS Duplex Board

We offer a wide gamut of duplex board boxes that are appropriate for various kinds of printing jobs. The products are made from a recycled paper which emphasis our green initiative of save trees. Our Best Quality HWC and LWC Duplex Boards are available in reel and sheet form.Read more -

Explore the Uses of Duplex Board & Parchment Paper at JK Paper Duplex Board

A duplex board is a sheet of twofold employ paper, just like the sort of thick paper used to make cards. It is frequently utilized as a part of the packaging and has an unmistakably smooth, practically waxy feel.Read more -

Duplex Board: An Overview Duplex Board

Duplex board, also known as white-lined chipboard, is a type of paperboard that is made from recycled paper and is commonly used for packaging, printing, and stationery products. It is known for its strength and durability, making it an ideal material for a variety of applications.Read more -

What is Duplex Board and what are its uses? Duplex Board

Duplex board is similar to paper board or cardboard. It is strong and thin and has a good appearance than cardboard. Duplex board can be manufactured with a smooth and glossy look as well as they can also be rough and un-bright in texture according to your needs.Read more -

What is the Difference Between Duplex Board and Triplex Board? Duplex Board

Have you ever gazed at packaging materials and wondered about the difference between a duplex board and a triplex board? It's a perplexing puzzle that even the packaging-savvy often find themselves contemplating. But fear not, for this blog post is about to untangle that enigma.Read more -

FURTHER PROCESSING OF DECOR PAPER DECORATION PAPER

Decor paper is mainly printed using the intaglio process. In this process, ink is applied to the paper by an engraved roller. Koehler decor paper can also be used in a digital printing process. The interplay between the paper color and various printing inks means the decorative design options are almost limitless.Read more -

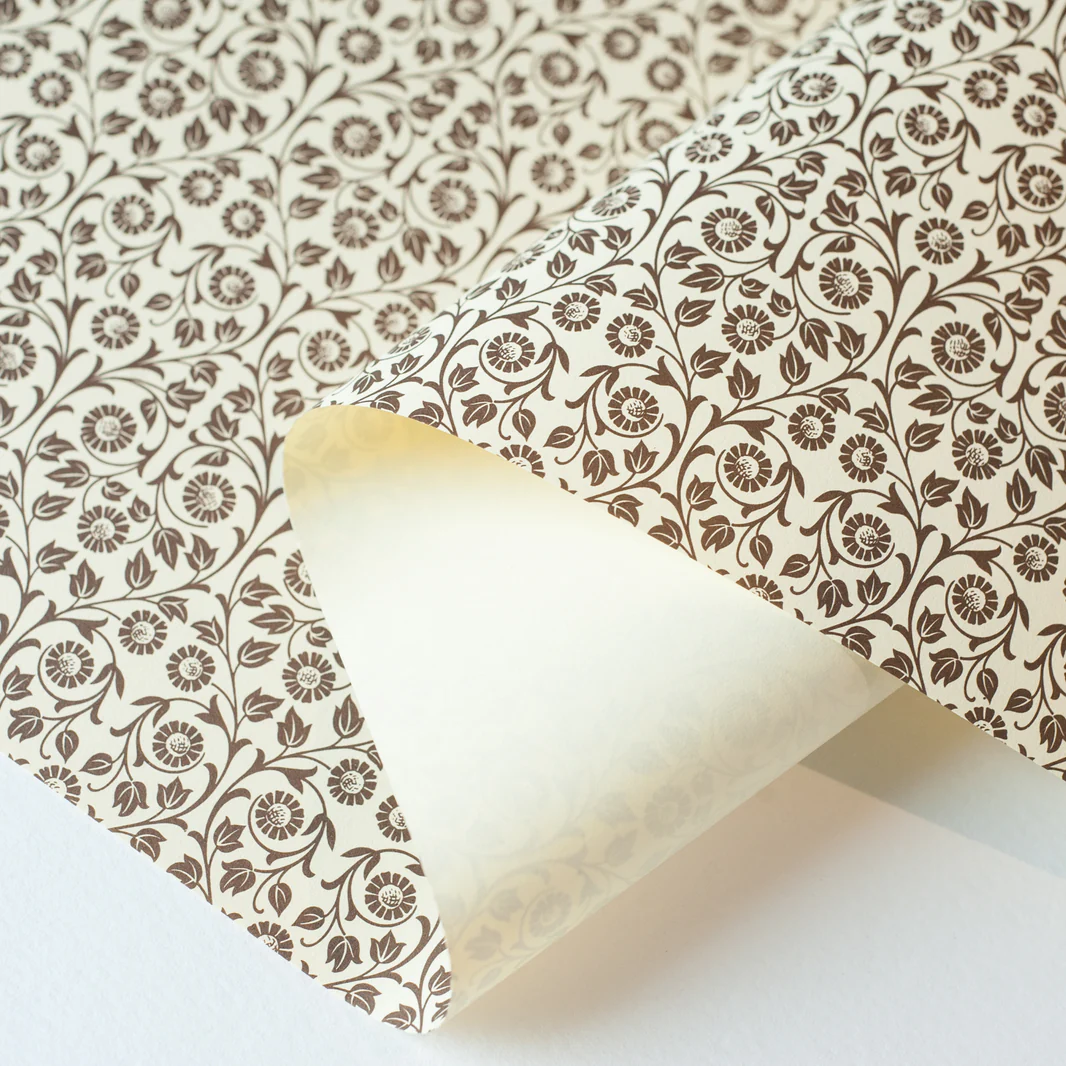

Reasons to Use Decoration Paper in Any Decorating Project DECORATION PAPER

Are you bored with the same old and traditional wood paneling? Do you want to find out about various designs and textures? Consider using decor paper for your next project. Decor paper is a printed paper used as a decorative finish for High-Pressure Decorative Laminate, Pre-Laminated Particle Boards, and MDF Boards.Read more -

TIPS TO CHOOSE DECORATIVE PAPER FOR FURNITURE DECORATION PAPER

There are different types of decorative paper available for furniture. You can choose from ornate papers, painted decor papers, PU decorative foil paper, and wood contact paper. Read this article to find out more. We have listed the different types of decorative papers and the different types of furniture they are ideal for. The following are a few tips for choosing the right type for your home. And don’t forget to experiment with the different options!Read more