- Cartref

- Everything You Need to Know About Duplex Board: Uses, Manufacturing, and Pricing

Tach . 29, 2024 11:06 Yn ôl i'r rhestr

Everything You Need to Know About Duplex Board: Uses, Manufacturing, and Pricing

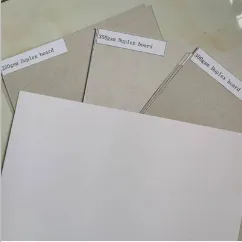

Duplex board is a versatile material widely used in packaging, printing, and other industries. Understanding duplex board uses, the duplex board manufacturing process, and duplex paper sheet price is crucial when deciding whether it’s the right material for your project. This guide will help you make an informed decision by highlighting key aspects of duplex board.

Duplex Board Uses: Versatile Applications for Various Industries

When considering duplex board uses, it’s important to note its versatility across various industries. Duplex board is a type of paperboard made from two layers of paper, providing strength and durability while maintaining flexibility. It is used in numerous applications, particularly in the packaging sector.

- Packaging: Duplex boardis widely used for packaging products ranging from food and beverages to cosmetics and pharmaceuticals. Its ability to be printed on makes it an ideal choice for retail boxes, product packaging, and displays.

- Printing: In the printing industry, duplex boardserves as a substrate for high-quality printed materials, including brochures, catalogs, and postcards.

- Eco-friendly Packaging: The growing demand for sustainable products has made duplex boardpopular in eco-friendly packaging. It is recyclable, making it a top choice for businesses that prioritize sustainability.

The board’s ability to combine strength and printability makes it a preferred choice for many industries looking to create both functional and aesthetically pleasing products.

Duplex Board Manufacturing Process: How It's Made

Understanding the duplex board manufacturing process helps highlight its quality and versatility. The process typically involves several steps to create a strong yet flexible board.

- Pulping: The process begins with the preparation of the pulp, made from wood fibers. This pulp is treated to improve its strength and texture.

- Forming: The pulp is then fed into a paper-making machine, where it is formed into sheets. The machine presses the pulp to form a continuous sheet of duplex board.

- Coating: Depending on the type of duplex board being produced, one side of the sheet may be coated to create a smooth, glossy finish. The uncoated side offers a more natural, matte appearance.

- Drying and Cutting: After coating, the sheets are dried, and the duplex board is cut to the required size for various applications, such as packaging, printing, or even as a backing material.

This process ensures that the duplex board has the necessary qualities, such as strength, durability, and printability, for its various uses.

Duplex Paper Sheet Price: Cost Factors and Pricing Trends

When it comes to purchasing duplex board, duplex paper sheet price is an important factor to consider. The price of duplex board can vary depending on several factors:

- Type of Duplex Board: The price can vary based on whether you are purchasing coated duplex board, uncoated duplex board, or grey back duplex board. Coated boards are typically more expensive due to the additional coating process.

- Quantity: Purchasing in bulk often results in a lower per-unit cost. If you're looking for a long-term supplier or need large quantities for a project, bulk pricing can offer significant savings.

- Quality: Higher quality duplex board, which offers better printability and durability, may come at a higher cost.

- Customization: Custom-sized boards or boards with specific features (such as special coatings or finishes) may come at a premium.

Despite these variables, duplex paper sheet price remains competitive and offers a cost-effective solution for businesses that require durable and high-quality packaging or printed materials.

Why Choose Duplex Board for Packaging and Printing?

There are many reasons to choose duplex board for packaging and printing. First, duplex board uses in packaging provide both strength and flexibility, making it ideal for creating durable boxes, product packaging, and displays. Its ability to be printed on with vivid colors and sharp images ensures that your product stands out on retail shelves.

Additionally, the duplex board manufacturing process ensures that the material is cost-effective while maintaining high standards of quality. It is strong enough to protect products during shipping and handling, yet lightweight enough to keep shipping costs down.

Finally, with duplex paper sheet price being relatively affordable compared to other premium paperboard options, duplex board provides a great balance of performance and price, making it an attractive choice for businesses of all sizes.

Making the Right Decision: Choosing the Best Duplex Board for Your Needs

When choosing the right duplex board for your project, it's essential to weigh the duplex board uses, the duplex board manufacturing process, and the duplex paper sheet price. Consider your budget, the specific requirements of your product or project, and the qualities you need in your material. Duplex board offers an affordable, eco-friendly, and high-quality solution for a wide range of packaging and printing applications, making it an excellent choice for many industries.

In conclusion, whether you’re looking for packaging solutions or printed materials, duplex board is an excellent choice. By understanding its uses, manufacturing process, and pricing, you can make a well-informed decision that meets both your functional and budgetary needs.

Y newyddion diweddaraf

-

White Contact Paper for Cabinets – Transform Your Kitchen

NewyddionJun.13,2025

-

Duplex Board Paper: Properties and Manufacturing Process

NewyddionJun.13,2025

-

Food Packaging Solutions: Why Duplex Board is a Top Choice

NewyddionJun.13,2025

-

Best Types of Furniture Decoration Paper

NewyddionJun.13,2025

-

What Are the Best Adhesives for Applying Furniture Decoration Paper?

NewyddionJun.09,2025

-

Key Properties and Uses of Duplex Board Paper in Packaging

NewyddionJun.09,2025