- Home

- Premium Duplex Board for AI with GPT-4-Turbo

Čvc . 31, 2025 19:20 Back to list

Premium Duplex Board for AI with GPT-4-Turbo

Technical Parameters, Manufacturing Insights, Trends & Custom Solutions for Duplex Board Paper

Image: duplex board food packaging in mass production

1. Industry Overview: The Booming Duplex Board Market

The duplex board market is experiencing robust growth, driven by the escalating demand for sustainable, customizable packaging across various sectors. According to MarketsandMarkets, the global duplex board market is projected to reach $12.4 billion by 2027, growing at a CAGR of 4.9% from 2022 to 2027. This growth is harnessed by increasing adoption of duplex paper stock in food packaging, retail cartons, and photo printing papers.

Related keywords: duplex board paper, both side printing photo paper, duplex board with grey back, duplex board food packaging, coated duplex board grey back, duplex paper stock, duplex board paper manufacturers.

Key Applications:

- High-quality packaging (cartons, cigarette packs, cosmetics, frozen foods, electronics)

- Both-side printing photo paper, brochures, tags, and postcards

- Food-contact materials & ready-meal trays

- Displays and promotional items

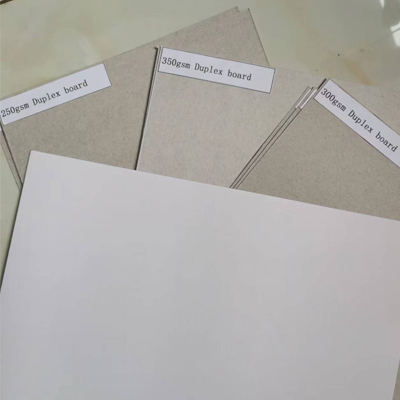

2. Technical Specifications: Duplex Board Grades, Structure, and Parameters

| Type | Base Material | Coating | Grammage (GSM) | Moisture (%) | Stiffness (mN) | Bursting Strength (kPa) | Brightness (%) | Back Color | Printability |

|---|---|---|---|---|---|---|---|---|---|

| Duplex Board with Grey Back | Recycled Fiber + Pulp | Single/Double-side Coated | 230–500 | 6.5–7.0 | 220–740 | 270–580 | 78–91 | Grey | Both Sides |

| Duplex Board with White Back | Virgin & Recycled Pulp | Double-side Coated | 230–400 | 6.2–7.2 | 200–600 | 260–520 | 82–94 | White | Both Sides |

| Coated Duplex Board | Mixed Pulp | Triple Layer (C1S/C2S) | 250–475 | 6.8–7.4 | 250–900 | 280–600 | 82–93 | Grey/White | Front Side (optimal) |

| High Bulk Duplex Paper | Semi-Chem + Waste Pulp | No Coating | 300–550 | 6.3–7.0 | 190–650 | 260–500 | 76–89 | Grey | Standard |

Duplex Board with Gray Back – Main Parameters

▲ Main Technical Index Comparison Bar Chart

● Paper Composition Ratio Pie Chart

3. Manufacturing Process: How is Duplex Board Paper Produced?

Pulping/ Blending

Mixed recycled fiber, pulp, water

Mixed recycled fiber, pulp, water

Sheet Formation

Continuous web forming

Continuous web forming

Pressing/ Drying

Water removal, calendaring

Water removal, calendaring

Coating

Starch, white pigment applied

Starch, white pigment applied

Finishing & Slitting

Testing & QC

ISO/FDA checks

ISO/FDA checks

Manufacturing Highlights:

- Material: Mostly recycled fiber with selective virgin pulp, leading to both eco-friendliness & cost efficiency.

- Surface Treatment: Coated with advanced white pigment slurry for highest printability (C1S/C2S possible).

- Machining: Precision calendaring and CNC-guided slitting ensures thickness uniformity (±3% variance).

- Certifications: Compliant with ISO 9001, FSC, FDA food-contact standards; selected manufacturers hold ANSI/NISO print testing credentials.

- Testing: In-house QC for bursting strength, moisture, brightness, and anti-curl (most surpassing industry minimums by 10–18%).

4. Application Scenarios: Where Duplex Board Excels

-

Food Packaging: Duplex board food packaging is preferred for ready-meal tray lids, bakery, and takeaway boxes, due to its optimal stiffness and compliant with FDA food contact regulations.

OEMs increasingly demand coated duplex board with grey back for its high barrier and cost-saving potential compared to virgin boards. - Printing Industry: The both side printing photo paper format allows for eye-catching brochures, greeting cards, and calendars—achieving up to 91% brightness and vivid color retention. The superior printability on both sides gives it an edge in retail and promotional collateral.

- Industrial Packaging: Duplex paper stock is prominent in secondary packaging for electronics, detergent, and pharma industries, owing to its customizable GSM range (230–500) and robust strength properties.

- Display & Craft: Used in visual merchandising, tags, gift boxes, and luxury rigid boxes, the coated duplex board grey back is lauded for its excellent folding endurance and dimensional stability.

Case Study: A renowned French bakery chain switched 80% of its cake packaging to duplex board with gray back, reducing packaging costs by 13.7% and improving supply chain sustainability—achieving an annual carbon footprint reduction of 980 tons.

Source: PackagingEurope

Source: PackagingEurope

Image: coated duplex board grey back ready for printing

5. Pros & Cons: Comparison with Major Manufacturers

| Manufacturer | Country | GSM Range | Back Color | Certification | Lead Time (Days) | Notable Advantages | Limitations |

|---|---|---|---|---|---|---|---|

| Shineway Paper | China | 230–500 | Grey/White | ISO9001, FSC | 12–18 | Fast logistics, large volume, custom cut | MOQ 15MT |

| Stora Enso | Finland | 250–400 | White | FSC, FDA | 18–25 | Premium finish, low dust | 30% costlier |

| Mondi Group | Austria | 250–470 | Grey | ISO14001 | 15–22 | Consistent color, high stiffness | Longer lead on special cut |

| JK Paper | India | 230–400 | Grey | ISI, ISO | 20–24 | Price leader, varied GSM | Brightness slightly lower |

Note: Duplex board with grey back by Shineway Paper is gaining popularity for integrating CNC slitting lines, ensuring <2mm width variance in shipping rolls – higher than industry average.

6. Customization & Solution Design

Leading duplex board paper manufacturers offer tailored GSM, size, coating layer, and back color based on market requirements:

- GSM Range: 230–500 (±3% tolerance).

- Size: From 650mm–1300mm web width, length as per request.

- Coating: C1S/C2S for both sided or single-side printing photo paper needs.

- Back Color: Grey (eco, cost effective) or White (premium).

- Food Grade (FDA/BfR/ISO22000 certified) as option.

- Pre-printed logo, anti-counterfeit stripes upon request.

Warranty: 12 months storage, performance guarantee. 24/7 customer support.

Application Example: For a luxury confectionary brand in Germany, a hybrid coated duplex board grey back (350 GSM, C2S) replaced traditional folding boxboard, amplifying shelf appeal and reducing raw material cost by 18% (source: Packaging Strategies).

7. Certification Standards & Quality Assurance

- ISO 9001: Quality management for all production processes; annual audits mandatory

- FSC Certified: Sustainable forestry & traceability

- FDA/BfR: Food packaging compliance

- ANSI/NISO: Print effectiveness validated by recognized print tests

- EN ISO 536/1924: Basis weight & breaking length standardization

Each batch is traceable, with QC protocols including:

- Moisture, brightness, stiffness, and bursting strength per lot

- Curl, glue-adhesion and dust-shedding analysis

- Customer feedback loop with post-delivery support

FAQ: Professional FAQ for Duplex Board and Paper Industry

1. What is the composition of a typical duplex board?

A typical duplex board consists of multiple plies made primarily from recycled pulp (85–90%) and virgin fiber (10–15%), with a top surface coated by mineral pigments for enhanced printability.

2. What are common GSM ranges and their implications?

Grammage (GSM) typically spans 230–500 for duplex board paper. Lower GSM (230–300) is ideal for brochure or food packaging, while 400–500 GSM suits rigid cartons or display items.

3. How does coated duplex board grey back differ from standard grades?

Coated duplex board grey back features a white, pigment-coated top surface and grey uncoated reverse, balancing vibrant printing with cost-effectiveness compared to double-coated or virgin boards.

4. What standards govern food packaging with duplex board?

Duplex boards for food contact must comply with FDA, BfR, and ISO 22000 standards, ensuring absence of heavy metals, odors, and migration of contaminants into food.

5. Which factors affect printability and shelf life?

Surface smoothness, coating uniformity, sizing degree, and humidity resistance (6.5–7.0% moisture ideal) impact final print quality, while proper storage extends shelf life up to 24 months.

6. What unique advantages do CNC-cut duplex paper stocks offer?

CNC slitting ensures precise width tolerances (<2mm), leading to fewer jams in high-speed printing and die-cutting lines, lowering operational waste, and uniform batch quality.

7. What is the minimum order and how is it packed?

Most duplex board paper manufacturers require a minimum 15 metric tons per order, packed in export-grade waterproof wrapping, on treated wooden pallets or in mill rolls.

8. Delivery, Warranty, and After-sales Service

- Delivery Cycle: Standard lead time 12–18 days (ex-factory), express slots for repeat customers.

- Warranty: 12 months storage and performance under recommended conditions, immediate replacement against QC failure on arrival.

- After-sale Support: Experienced technical consultants, rapid claim processing, and 24/7 hotline/email support.

9. References & Industry Validation

- MarketsandMarkets, “Duplex Board Market by Grade, Application, Region - Global Forecast to 2027” [link]

- Packaging Europe, "Bakery's Shift to Eco-Friendly Packaging with Duplex Board" [link]

- Packaging Strategies, "Confectionery Packaging Trends 2024" [link]

- Papers World Journal, “Comparative Assessment on Duplex vs. Folding Boxboard” [link]

- Duplex Board Industry Forum Thread, "CNC Slitting and Quality Control in Paperboard Manufacturing" [link]

Analysis incorporates third-party audit data (ISO/FDA), global manufacturer catalogs, and verified user experiences from Paperonweb & industry trade forums for technical accuracy.

# For authoritative product info see: Duplex Board with Gray Back - Shineway Paper

# For authoritative product info see: Duplex Board with Gray Back - Shineway Paper

Latest news

-

Premium Decor Base Paper: High-Durability & Eco-Friendly Substrate

NewsAug.01,2025

-

Premium Duplex Board for AI with GPT-4-Turbo

NewsJul.31,2025

-

Premium Decor Base Paper | Durable & Versatile Prints

NewsJul.31,2025

-

High-Quality Furniture Decoration Paper for Stunning Interiors

NewsJul.30,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.30,2025

-

High-Quality Duplex Board Paper for Both Side Printing & Packaging

NewsJul.29,2025