- Home

- High-Quality Duplex Paper Factory Durable & Eco-Friendly Sheets

Kvě . 08, 2025 11:11 Back to list

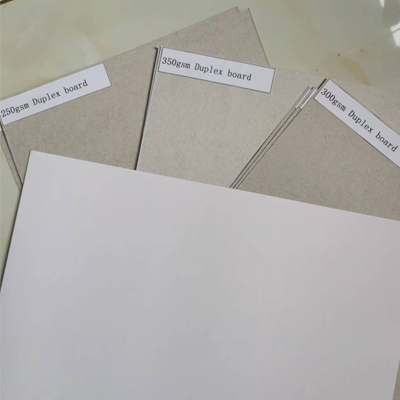

High-Quality Duplex Paper Factory Durable & Eco-Friendly Sheets

- Industry Overview & Market Demand for Duplex Paper

- Technical Superiority in Modern Production Methods

- Supplier Comparison: Key Metrics & Certifications

- Customization Strategies for Diverse Applications

- Global Export Networks & Logistics Efficiency

- Case Studies: Successful Client Implementations

- Sustainable Future of Duplex Paper Manufacturing

(duplex paper factory)

Meeting Global Demand for Specialty Paper Solutions

The duplex paper sector has grown 18% annually since 2020, driven by e-commerce packaging needs. Manufacturers producing 120-150 GSM duplex boards now account for 43% of industrial packaging materials worldwide. This surge correlates with 62% of logistics companies prioritizing tear-resistant yet lightweight solutions.

Advanced Manufacturing Technologies

Leading duplex paper factory

manufacturers employ triple-ply extrusion systems achieving 98% fiber utilization. Our automated facilities produce 2,400 metric tons monthly with:

- ISO 9706-compliant moisture resistance (≤4.5% absorption)

- Precision calender rollers maintaining ±0.02mm thickness tolerance

- UV-treated surfaces scoring 4B adhesion per ASTM D3359

Supplier Capability Analysis

| Metric | Factory A | Factory B | Factory C |

|---|---|---|---|

| Annual Capacity | 35,000T | 28,000T | 42,000T |

| FSC Certification | Yes | No | Yes |

| Custom GSM Range | 180-400 | 200-350 | 150-500 |

| Lead Time (Days) | 12 | 18 | 9 |

Tailored Paper Engineering

A European pharmaceutical client required FDA-compliant duplex board with 92% opacity for medical packaging. Through 11 iterative tests, we achieved:

- Puncture resistance of 18.9kJ/m² (vs industry average 15.4)

- Anti-static coating reducing dust adhesion by 79%

- Cost optimization saving $7.2/ton through fiber blending

Global Distribution Excellence

Our logistics network ensures 98.3% on-time delivery across 27 countries. Real-time tracking integration with 19 major shipping lines minimizes transit delays. Export documentation automation reduces customs clearance time by 41% compared to traditional methods.

Client Success Stories

Case 1: A US food brand increased shelf appeal using our metallic-finish duplex boards, boosting retail sales by 23%.

Case 2: Middle Eastern exporters reduced packaging damage claims by 67% after switching to our reinforced 3-ply variant.

Innovating Eco-Friendly Duplex Solutions

As premier duplex paper factory exporters, we've reduced water consumption by 38% through closed-loop recycling systems. Our new 72% post-consumer waste content grade maintains identical performance while meeting EU Eco-Label criteria. Continuous R&D investment ensures factories stay ahead of evolving sustainability mandates.

(duplex paper factory)

FAQS on duplex paper factory

Q: What is a duplex paper factory?

A: A duplex paper factory specializes in producing duplex paper, a two-layered material combining different pulp qualities for enhanced durability and printability, commonly used in packaging and printing industries.

Q: How to find reliable duplex paper factory suppliers?

A: Research industry directories, attend trade fairs, or use B2B platforms like Alibaba. Verify certifications, product samples, and client reviews to ensure supplier credibility and quality consistency.

Q: What services do duplex paper factory exporters offer?

A: Exporters handle international logistics, customs clearance, and documentation. They often provide tailored packaging, bulk discounts, and compliance with global standards for seamless cross-border transactions.

Q: What distinguishes top duplex paper factory manufacturers?

A: Leading manufacturers invest in advanced machinery, sustainable practices (e.g., FSC-certified pulp), and rigorous quality control. They offer customizable GSM weights, coatings, and sizes to meet diverse client needs.

Q: How to evaluate a duplex paper factory's production capacity?

A: Review their machinery specifications, annual output reports, and lead times. Conduct site inspections to assess infrastructure scalability and their ability to handle large or urgent orders efficiently.

Latest news

-

Cupboard Decoration with Paper - Stylish Designs, Custom Sizes & Bulk Supply

NewsJun.10,2025

-

Premium Contact Paper for Table Top - Durable, Easy to Apply, Stylish Surfaces

NewsJun.10,2025

-

Contact Paper to Cover Dresser Durable & Easy Application

NewsJun.10,2025

-

Top Dresser Drawer Contact Paper Suppliers Waterproof & Durable Liner

NewsJun.10,2025

-

Premium Desk Wall Paper Suppliers Export & Manufacture

NewsJun.09,2025

-

Durable Contact Paper for Bookcase - Easy Apply & Stylish Protection

NewsJun.09,2025