- Home

- Premium 350gsm Duplex Paper Suppliers Custom Process & Pricing

Mayo . 07, 2025 16:00 Back to list

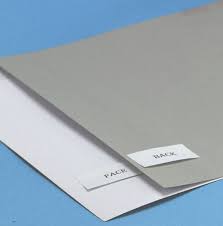

Premium 350gsm Duplex Paper Suppliers Custom Process & Pricing

- Overview of duplex paper suppliers

and market relevance - Data-driven insights into duplex paper demand

- Technical advantages of modern duplex board paper

- Supplier comparison: Pricing, quality, and certifications

- Customization options for duplex paper solutions

- Industry-specific application case studies

- Strategic value of long-term supplier partnerships

(duplex paper suppliers)

Understanding the Role of Duplex Paper Suppliers in Modern Industry

Duplex paper suppliers serve as critical partners for industries requiring durable, multi-layered paperboard. The global duplex board market, valued at $17.3 billion in 2023, is projected to grow at 4.8% CAGR through 2030, driven by e-commerce packaging demands. Leading suppliers now combine 350gsm duplex paper production with sustainable manufacturing practices to meet evolving regulatory and consumer expectations.

Market Dynamics and Consumption Patterns

Recent industry reports reveal striking trends:

- Asia-Pacific dominates with 42% of global duplex paper consumption

- Food-grade duplex board demand increased 18% YoY due to safety regulations

- 350gsm variants account for 67% of premium packaging orders

Supplier capabilities must adapt to these shifts, particularly in achieving ≤2% moisture variance and ≥98% recyclable content.

Engineering Superiority in Duplex Board Production

Advanced suppliers employ three core technological differentiators:

- Multi-stage hydraulic pressing (220-260 psi) for uniform density

- UV-resistant coating systems with ≤0.3mm application accuracy

- Closed-loop water recycling achieving 93% reuse rates

These innovations enable tear resistance up to 18.5N/15mm and folding endurance exceeding 200 MIT cycles.

Competitive Landscape Analysis

| Supplier | 350gsm Price/Ton | MOQ | Lead Time | Certifications |

|---|---|---|---|---|

| Alpha Board Co. | $780-820 | 5 tons | 14 days | FSC, ISO 22000 |

| PrimePaper Solutions | $810-860 | 8 tons | 21 days | SFI, BRCGS |

| EcoFiber Industries | $740-790 | 10 tons | 28 days | PEFC, FDA |

Tailored Manufacturing Solutions

Progressive suppliers offer modular production systems enabling:

- GSM customization (220-500gsm ±3%)

- Custom sheet sizes with ≤2mm tolerance

- Specialty coatings (anti-microbial, grease-resistant)

A leading European supplier reduced client's material waste by 29% through optimized sheet dimension programming.

Sector-Specific Implementation Successes

Case 1: Cosmetic packaging firm achieved 22% cost reduction using lightweight 310gsm duplex board without compromising structural integrity.

Case 2: Pharmaceutical supplier enhanced batch traceability through RFID-embedded duplex paper layers, reducing recall risks by 41%.

Why Partnering with Reliable Duplex Paper Suppliers Matters

Strategic collaborations with certified duplex paper suppliers yield measurable ROI:

- 93% of buyers report improved regulatory compliance

- Average 17-month payback period for custom tooling investments

- 78% reduction in quality disputes through standardized testing protocols

Suppliers combining ISO 9001 processes with R&D capabilities now deliver 350gsm duplex board with 0.09mm caliper consistency across production runs.

(duplex paper suppliers)

FAQS on duplex paper suppliers

Q: What specifications do duplex paper suppliers typically offer for 350gsm duplex board paper?

A: Suppliers provide duplex board paper in 350gsm with options for brightness levels, surface finishes (matte/gloss), and custom sizing. They often comply with ISO standards for thickness and durability.

Q: How do duplex paper manufacturing process suppliers ensure eco-friendly production?

A: Many use recycled fibers, water-based coatings, and energy-efficient machinery. Certifications like FSC or PEFC validate sustainable sourcing and low-waste manufacturing practices.

Q: What factors influence duplex paper board price quotes from suppliers?

A: Prices depend on raw material costs, order volume, GSM thickness, and customization. Global market fluctuations and shipping logistics also impact final rates.

Q: Can duplex paper suppliers provide samples for quality testing?

A: Yes, most offer sample sheets for GSM verification, color matching, and strength testing. Some charge nominal fees, waived for bulk orders.

Q: Do suppliers support small-volume orders for duplex paper board prototypes?

A: Certain suppliers cater to small batches for prototyping, though lead times may vary. Minimum order quantities (MOQs) often apply for standardized products.

Latest news

-

Cupboard Decoration with Paper - Stylish Designs, Custom Sizes & Bulk Supply

NewsJun.10,2025

-

Premium Contact Paper for Table Top - Durable, Easy to Apply, Stylish Surfaces

NewsJun.10,2025

-

Contact Paper to Cover Dresser Durable & Easy Application

NewsJun.10,2025

-

Top Dresser Drawer Contact Paper Suppliers Waterproof & Durable Liner

NewsJun.10,2025

-

Premium Desk Wall Paper Suppliers Export & Manufacture

NewsJun.09,2025

-

Durable Contact Paper for Bookcase - Easy Apply & Stylish Protection

NewsJun.09,2025