- Home

- oem coated duplex board with grey back

Des . 18, 2024 08:47 Back to list

oem coated duplex board with grey back

Understanding OEM Coated Duplex Board with Grey Back

In the realm of packaging and printing, the choice of materials plays a pivotal role in determining both functionality and aesthetics. One such material that has gained significant attention is the OEM coated duplex board with a grey back. This versatile substrate is widely used in packaging, especially for products that require a balance of strength, print quality, and visual appeal.

What is Duplex Board?

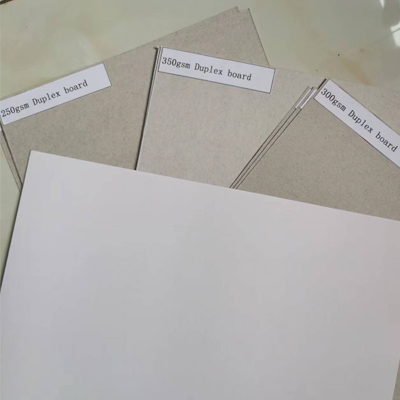

Duplex board is a type of paperboard that is made from recycled paper and consists of two layers. The front side is generally coated to provide a smooth surface suitable for printing, while the back side is typically grey in color. This grey back serves several purposes, including providing additional opacity and making the board more rigid. The coated front layer is designed to enhance the vibrancy and clarity of printed images, making it an ideal choice for packaging applications that demand high-quality visuals.

Importance of OEM Coating

OEM (Original Equipment Manufacturer) coating refers to a specialized surface treatment that enhances the properties of duplex board. This coating not only improves printability but also offers excellent graphics reproduction, ensuring that colors appear vibrant and true to life. The OEM coating process involves applying a protective layer that can resist moisture and abrasion, thereby extending the life of the printed product. Additionally, the coating can be tailored to achieve different finishes, such as gloss, matte, or satin, depending on the desired effect for the final product.

Applications of OEM Coated Duplex Board

OEM coated duplex board with a grey back is widely used in various industries, including retail, food and beverage, cosmetics, and pharmaceuticals. It is commonly employed for making boxes, cartons, display packaging, and promotional materials. The grey back provides a sturdy foundation, making it suitable for products that require extra protection and durability. This substrate is also an environmentally friendly option since it is primarily made from recycled materials, catering to the increasing demand for sustainable packaging solutions.

oem coated duplex board with grey back

Advantages of Using OEM Coated Duplex Board

1. Excellent Print Quality The smooth coated surface allows for high-resolution printing, making it ideal for intricate designs and vibrant colors.

2. Durability The grey back adds strength and stability to the board, ensuring it can withstand the rigors of transportation and handling.

3. Versatility Due to its adaptability, OEM coated duplex board can be used in various designs and applications, from elegant product packaging to eye-catching promotional displays.

4. Sustainability Utilizing recycled materials aligns with global efforts to reduce waste and promote eco-friendly practices, appealing to environmentally conscious consumers.

5. Cost-Effectiveness Given its strength and versatility, duplex board offers excellent value for money, making it a preferred choice for many manufacturers and brands.

Conclusion

In summary, OEM coated duplex board with a grey back represents a perfect marriage of functionality and aesthetics in the packaging industry. Its excellent print quality, durability, versatility, and sustainability make it an attractive option for businesses looking to create striking, effective packaging solutions. As companies continue to prioritize both environmental considerations and consumer demands for high-quality products, the adoption of materials like OEM coated duplex board will likely increase. For those seeking to enhance their packaging offerings, understanding the benefits and applications of this material is essential in making informed decisions that cater to both market needs and environmental stewardship.

Latest news

-

Premium Contact Paper Over Desk – Durable & Stylish Desk Cover Solutions

NewsJul.05,2025

-

High-Quality Duplex Board Food Packaging - Reliable Suppliers & Exporters

NewsJul.05,2025

-

Duplex Paper Rate Per Kg – Best Manufacturer & Supplier Prices Online

NewsJul.04,2025

-

High-Quality Duplex Kraft Paper Reliable Suppliers & Exporters Top Manufacturers

NewsJul.04,2025

-

Removable Contact Paper for Kitchen Cabinets - Durable, Easy to Install, Stylish Designs

NewsJun.24,2025

-

Cupboard Decoration with Paper - Stylish Designs, Custom Sizes & Bulk Supply

NewsJun.10,2025