- Home

- Premium Coated Duplex Board Paper - Grey & White Back

Sep . 13, 2025 08:20 Back to list

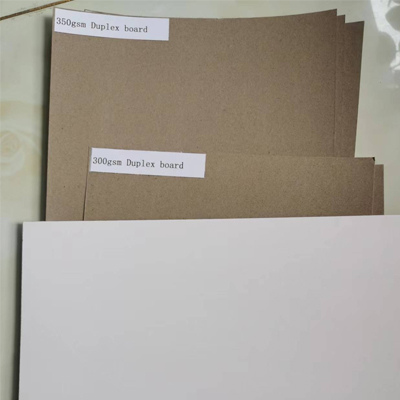

Premium Coated Duplex Board Paper - Grey & White Back

Understanding Duplex Board Paper: A Comprehensive B2B Guide

In the dynamic world of packaging and printing, the selection of appropriate substrates is paramount for product protection, visual appeal, and cost-effectiveness. Among the myriad options available, duplex board paper stands out as a highly versatile and economical choice. This engineered paperboard, characterized by its multi-layered structure, offers a unique blend of rigidity, printability, and strength, making it indispensable across various industries. This comprehensive guide delves into the technical aspects, manufacturing processes, application scenarios, and market trends surrounding this critical material, providing B2B decision-makers with the insights needed to optimize their packaging solutions.

Manufacturing Process Flow of Duplex Board Paper

The production of duplex board paper is a sophisticated industrial process, meticulously designed to achieve specific structural and surface properties. It primarily involves the layering of different pulp types, often utilizing recycled materials for the core and back layers, combined with virgin pulp or higher-grade recycled pulp for the top, printable surface. This multi-ply construction is key to its characteristic strength and cost efficiency.

Schematic Steps:

- Pulping & Fiber Preparation: Recycled paper materials (waste paper, cardboard) are collected, sorted, and then pulped in hydrapulpers with water and chemicals to separate the fibers. Virgin wood pulp may be used for the top layer, processed similarly.

- Refining: The pulp slurry undergoes mechanical refining to enhance fiber bonding properties and improve strength. Different refining levels are applied to pulps designated for different layers (top, middle, back).

- Multi-Layer Sheet Forming: Distinct pulp slurries (e.g., higher-grade for the top, lower-grade for the middle/back) are fed into multiple headboxes of a paper machine. These headboxes deposit the slurries onto a moving wire mesh, forming individual layers that are then combined while still wet, creating a unified multi-ply sheet. This process is crucial for achieving the desired structure, such as coated duplex board grey back or duplex board white back.

- Pressing & Drying: The wet sheet passes through press sections to remove excess water mechanically. Subsequently, it enters a dryer section, typically a series of heated cylinders, to evaporate remaining moisture until the desired moisture content is achieved.

- Surface Sizing & Coating: For enhanced surface properties, the paperboard may undergo surface sizing to improve strength and reduce porosity. A crucial step for coated duplex board is the application of a coating layer (often clay-based) to the top surface. This coating improves brightness, smoothness, and printability, allowing for high-quality graphics.

- Calendering: The coated or uncoated board passes through calender stacks (rollers) to compact the fibers, smooth the surface, and achieve the desired thickness (caliper) and gloss.

- Slitting & Winding: The continuous paperboard web is trimmed to the required width and wound into large parent rolls, ready for further processing or shipment.

Product Materials: Typical materials include recycled mixed paper, de-inked pulp (for grey back layers), and bleached chemical pulp or mechanical pulp (for white top layers). Testing Standards: Manufacturers adhere to international standards such as ISO 9001 for quality management, ISO 14001 for environmental management, and often comply with industry-specific standards for packaging materials concerning food contact safety (e.g., FDA, BfR recommendations where applicable) and heavy metal content (e.g., RoHS). Key physical properties are tested according to TAPPI or ISO methods (e.g., ISO 536 for grammage, ISO 2493 for stiffness, ISO 535 for Cobb value).

Technical Specifications and Parameters

The performance of duplex board is defined by a set of critical technical parameters that directly influence its suitability for various applications. Understanding these specifications is essential for selecting the correct grade for specific packaging and printing needs.

| Parameter | Unit | Typical Range (150-450gsm) | Test Method |

|---|---|---|---|

| Grammage | gsm (g/m²) | 150 - 450 | ISO 536 |

| Caliper (Thickness) | µm | 200 - 700 | ISO 534 |

| Brightness (Top Side) | % ISO | 80 - 88 | ISO 2470 |

| Stiffness (MD) | mN·m | 100 - 6000 | ISO 2493 |

| Stiffness (CD) | mN·m | 40 - 2500 | ISO 2493 |

| Bursting Strength | kPa | 300 - 1200 | ISO 2758 |

| Cobb Value (60s) | g/m² | 25 - 40 | ISO 535 |

| Surface Roughness (PPS) | µm | 1.0 - 2.5 | ISO 8791-4 |

| Moisture Content | % | 6.0 - 8.0 | ISO 287 |

Key Terminology Explained:

- Grammage (gsm): Mass per unit area, indicating the paperboard's substance and influencing rigidity.

- Caliper: The thickness of the sheet, crucial for die-cutting, creasing, and overall package integrity.

- Brightness: A measure of light reflectance, particularly important for the top surface to ensure vibrant print reproduction.

- Stiffness: Resistance to bending, measured in machine direction (MD) and cross direction (CD). High stiffness is vital for structural integrity in packaging.

- Bursting Strength: The maximum pressure a material can withstand before rupturing, indicating resistance to external forces.

- Cobb Value: A measure of water absorptiveness, important for printability and resistance to moisture. Lower values indicate better water resistance.

- Surface Roughness (PPS): Indicates the smoothness of the surface, directly affecting print quality and ink absorption.

Industry Trends & Market Dynamics

The market for duplex board paper is influenced by several global trends. There's a growing emphasis on sustainable packaging solutions, driving demand for materials with high recycled content. This aligns perfectly with the typical composition of duplex board, especially grades like duplex board grey back. Furthermore, the rise of e-commerce has amplified the need for durable yet lightweight packaging that can withstand the rigors of shipping while minimizing freight costs. Innovations in coating technologies are also enhancing the printability and barrier properties of coated duplex board, opening up new application possibilities in areas previously dominated by more expensive materials. The global paperboard packaging market is projected to grow, with a significant contribution from duplex board due to its cost-effectiveness and versatility, particularly in emerging economies.

The demand for aesthetic appeal in consumer goods packaging also pushes manufacturers to improve surface finishes and print fidelity of coated duplex board, ensuring brands can maintain a premium perception even with economical packaging.

Application Scenarios and Target Industries

The versatility of duplex board makes it suitable for a vast array of packaging and printing applications across numerous industries. Its balanced properties — stiffness for structural integrity, printability for branding, and cost-efficiency for mass production — drive its widespread adoption.

- Pharmaceuticals: Used for packaging non-sterile medicines, medical devices, and health supplements, where clear branding and informational printing are crucial.

- Cosmetics & Personal Care: Ideal for packaging individual cosmetic items, soaps, toothpaste, and other personal care products, benefiting from the excellent print surface of coated duplex board with grey back for premium visuals.

- Food & Beverage (Non-direct Contact): Employed for outer packaging of cereals, snacks, frozen foods, tea, coffee, and confectionery. While not always suitable for direct food contact, it provides robust secondary packaging.

- Electronics & Appliances: For small electronic gadgets, light bulbs, and components, providing protective yet visually appealing retail packaging.

- Textiles & Apparel: Used for shirt boxes, hosiery packaging, and general apparel boxes.

- General Packaging & Stationery: Broadly used for toy boxes, shoe boxes, matchboxes, and various stationery items like file covers and notepads.

Typical Application Advantages:

- Cost-Effectiveness: A primary advantage, especially for high-volume consumer goods, making it a preferred choice over solid bleached sulfate (SBS) board where cost is a major factor.

- Excellent Printability: The smooth, often coated, white surface ensures high-fidelity graphic reproduction, vibrant colors, and sharp text, crucial for brand differentiation.

- Rigidity and Strength: The multi-ply construction provides good bending stiffness and bulk, offering adequate protection for packaged goods during transit and handling.

- Eco-Friendliness: High recycled content (especially in grey back variants) supports corporate sustainability goals and appeals to environmentally conscious consumers.

- Versatility: Can be easily converted through various finishing processes such as cutting, creasing, folding, gluing, varnishing, and laminating.

Vendor Comparison: Duplex Board vs. Other Packaging Boards

Choosing the right paperboard involves weighing various factors including cost, performance, and aesthetic requirements. While duplex board paper excels in many areas, understanding its position relative to other common packaging boards is crucial.

| Feature | Duplex Board (Coated Grey Back) | Folding Boxboard (FBB / GC1) | Solid Bleached Sulfate (SBS / SBB) | Chipboard (Uncoated Grey Back) |

|---|---|---|---|---|

| Primary Material | Recycled pulp (middle/back), virgin/de-inked (top) | Virgin mechanical pulp (middle), virgin chemical pulp (top/back) | Virgin bleached chemical pulp | 100% Recycled pulp |

| Top Surface | Coated white | Coated white | Coated white | Uncoated brown/grey |

| Back Surface | Grey/Brown (uncoated) | White (coated/uncoated) | White (coated/uncoated) | Grey/Brown (uncoated) |

| Printability | Excellent (top side) | Excellent | Superior | Fair (limited graphics) |

| Rigidity/Stiffness | Good | Very Good | Excellent | Moderate |

| Food Contact Safety | Indirect contact generally safe, direct requires specific grades/barriers | Generally suitable for direct food contact | Widely used for direct food contact | Not recommended for food contact |

| Cost-effectiveness | High | Medium | Low (Premium) | Very High |

| Typical Applications | General packaging, cosmetics, pharmaceuticals, food (secondary) | Food packaging, pharmaceuticals, confectionery, premium general packaging | High-end cosmetics, pharmaceuticals, food packaging, graphic applications | Basic inner packaging, stiffeners, partitions, industrial applications |

This comparison highlights that duplex board offers an optimal balance between performance and cost, positioning it as a robust solution for a vast segment of the packaging market where high-quality aesthetics are required without the premium price of virgin fiberboards.

Customized Solutions and Value-Added Services

Beyond standard sheets and rolls, reputable suppliers of duplex board paper offer extensive customization options to meet specific client requirements. This includes bespoke grammages and calipers, custom sheet sizes, specialized coatings, and finishing treatments.

- Grammage & Caliper Optimization: Tailoring the board's weight and thickness for optimal structural integrity or lighter packaging solutions.

- Surface Treatments: Options like high-gloss varnish, matte finishes, or specialized barrier coatings for enhanced moisture, grease, or oxygen resistance. This can transform standard coated duplex board into a specialized packaging material.

- Die-Cutting & Creasing: Pre-cut or creased sheets according to client-specific designs, ready for folding and assembly, saving considerable time and cost in the conversion process.

- Color Matching: For the back side, if a specific aesthetic is required (e.g., specific shade of brown back or grey back).

- Certification Compliance: Providing boards certified for specific environmental (e.g., FSC) or safety standards (e.g., food-grade compliance for indirect contact) to meet regulatory or brand requirements.

Working with a supplier capable of offering such bespoke solutions ensures that the final packaging material perfectly aligns with product specifications, brand identity, and operational efficiency goals.

Application Case Studies

Real-world applications demonstrate the tangible benefits of selecting duplex board paper for various packaging challenges.

Case Study 1: Consumer Electronics Packaging

A leading electronics manufacturer sought a cost-effective yet visually appealing packaging solution for its new line of smart home devices. The requirements included excellent print reproduction for high-resolution product imagery and sufficient rigidity to protect sensitive components during shipping. They opted for a 250 gsm coated duplex board white back.

- Solution: Customized sheets with high-gloss coating for vibrant graphics.

- Outcome: Achieved significant cost savings (approx. 15% compared to FBB) while maintaining premium brand aesthetics. The board's stiffness provided ample protection, reducing product damage rates by 5%.

- Client Feedback: "The print quality on the duplex board was exceptional, allowing our product's sophisticated design to truly shine. The cost savings were a crucial factor for our high-volume production."

Case Study 2: Pharmaceutical Outer Cartons

A pharmaceutical company needed packaging for over-the-counter medications that required precise printing for dosage instructions and branding, along with high structural integrity for stacking and shelf presence. They chose a 300 gsm coated duplex board with grey back.

- Solution: Board with optimized surface smoothness and brightness for clear text and graphics, ensuring compliance with regulatory labeling.

- Outcome: Excellent runnability on high-speed packaging lines, minimizing waste. The robust nature of the board ensured cartons retained their shape and protected the contents effectively, even in humid environments.

- Service Life: Estimated service life of packaging materials is typically aligned with the product's shelf life, often ranging from 1 to 5 years, ensuring product integrity until consumption.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between duplex board grey back and white back?

A: The primary difference lies in the back layer's composition and appearance. Grey back utilizes mixed recycled pulp, giving it a greyish hue, ideal for cost-effective packaging where the back is not visible. White back typically uses de-inked or bleached pulp for the back layer, providing a cleaner, whiter appearance on both sides, preferred for packaging where both interior and exterior aesthetics are important.

Q: Is duplex board paper environmentally friendly?

A: Yes, particularly duplex board grey back grades, which often contain a high percentage of recycled fibers. This makes them a more sustainable option compared to virgin fiberboards, reducing landfill waste and conserving natural resources. Many manufacturers also hold FSC or PEFC certifications.

Q: Can duplex board be used for food packaging?

A: Duplex board is widely used for secondary food packaging (e.g., cereal boxes, biscuit boxes, tea boxes). For direct food contact, specialized grades with food-safe coatings or laminations are required, or a barrier material must be used. Always confirm with the supplier for specific food-grade certifications.

Q: What is the typical lead time for custom orders?

A: Lead times vary based on order volume, customization complexity, and current production schedules. Standard orders for common grammages and sizes typically range from 7-14 business days. Custom grammages, special coatings, or large volumes may require 3-5 weeks. We advise discussing specific project timelines with our sales team for accurate estimates.

Q: What are the warranty commitments and after-sales support like?

A: We stand by the quality of our duplex board paper products. All materials are guaranteed to meet stated technical specifications and industry standards (e.g., ISO). In the rare event of a quality issue, we offer comprehensive after-sales support, including material analysis, replacement, or credit, depending on the nature of the issue. Our technical support team is available to assist with any application or processing queries to ensure optimal performance.

Conclusion

Duplex board paper represents a cornerstone in the packaging and printing industries, offering an unparalleled combination of performance, versatility, and economic efficiency. Its multi-layered structure, coupled with advanced coating technologies, provides a robust platform for diverse applications, from consumer goods to pharmaceuticals. As industries continue to evolve, driven by sustainability goals and consumer demands for engaging packaging, the role of duplex board will only grow, cementing its status as a critical material for B2B stakeholders seeking optimal solutions.

References

- International Organization for Standardization (ISO) - Official website for standards development.

- Technical Association of the Pulp and Paper Industry (TAPPI) - Resources on paper and packaging testing methods.

- Forest Stewardship Council (FSC) - Information on sustainable forest management and certification.

- Packaging World Magazine - Industry news and trends in packaging technology.

- Smithers Pira - Market research and consulting on packaging, paper, and print.

Latest news

-

Discover High Quality Self Adhesive Paper for Cabinets – Durable, Sustainable, Stylish

NewsNov.24,2025

-

Premium High Quality Blue Contact Paper for Furniture | Durable Surface Solutions

NewsNov.23,2025

-

What Drives High Quality Duplex Paper Price? Key Factors and Global Insights

NewsNov.22,2025

-

High Quality Decorative Contact Paper for Cabinets | Durable & Stylish Solutions

NewsNov.22,2025

-

High Quality Stick Paper for Cabinets: Durable, Sustainable, and Stylish Surface Solutions

NewsNov.21,2025

-

High Quality Self Adhesive Cabinet Paper: Durable, Sustainable Finishes for Modern Cabinets

NewsNov.20,2025