- Home

- Premium Duplex Kraft Paper Durable & Eco-Friendly Packaging Solutions

Jun . 06, 2025 16:54 Back to list

Premium Duplex Kraft Paper Durable & Eco-Friendly Packaging Solutions

- Understanding the Fundamentals of Multi-Layered Packaging Material

- Technical Advantages That Distinguish Quality Products

- Market Performance Metrics and Growth Statistics

- Comparative Analysis of Leading Global Suppliers

- Customizable Solutions for Industry-Specific Requirements

- Real-World Application Scenarios Across Industries

- Selecting Reliable Duplex Kraft Paper Exporters and Partners

(duplex kraft paper)

Understanding the Fundamentals of Duplex Kraft Paper

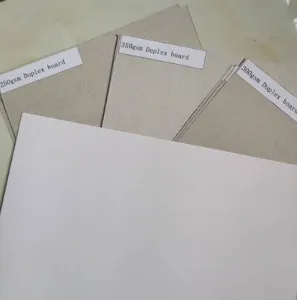

Duplex kraft paper combines multiple layers of kraft paper through specialized lamination processes to create enhanced material properties. This composite material typically features two distinct layers - a smooth top surface optimized for printing and a coarse bottom layer providing structural strength. The manufacturing involves hydrapulping technology where wood fibers are chemically treated to create long, interlocking cellulose chains that provide exceptional tear resistance.

The physical specifications include basis weights ranging from 180-400 GSM, with tensile strength reaching 50-90 N/m² and bursting strengths between 300-550 kPa. Material composition varies between 100% virgin fibers or recycled content blends (30-80% PCR), with regional availability affecting pricing by 15-25%. Porosity ranges from 100-300 ml/min, making it suitable for both breathable and barrier packaging applications when combined with specialized coatings.

Technical Advantages That Distinguish Quality Products

Advanced duplex kraft paper

outperforms standard alternatives through multiple material properties. The dual-layer configuration delivers 40% higher tear resistance than single-ply options while reducing basis weight by approximately 15%. This translates to significant shipping weight reductions, with logistics cost savings estimated at $0.02-$0.05 per product unit. The naturally porous cellulose structure offers superior breathability characteristics, maintaining optimal humidity levels for sensitive products like agricultural goods and electronics components.

Modern surface treatment technologies including nano-coatings and silicone impregnation enhance functional properties. These treatments create moisture barriers achieving 98% vapor resistance while maintaining the paper's compostability. Recent manufacturing innovations have also improved printability metrics - ink adhesion has increased by 30% compared to conventional kraft papers, with color gamut coverage expanding by 25% for brand-critical applications. Furthermore, the material retains its recyclability index of 95+, qualifying for circular economy certifications in major markets.

Market Performance Metrics and Growth Statistics

The global duplex kraft paper market is experiencing robust expansion, projected to reach $4.8 billion by 2028 with a compound annual growth rate of 6.3%. This growth is unevenly distributed across regions, reflecting varying industrial adoption patterns:

| Region | Current Market Share | Growth Rate (CAGR) | Key Growth Driver |

|---|---|---|---|

| Asia-Pacific | 42% | 8.1% | E-commerce packaging boom |

| North America | 28% | 5.2% | Sustainable packaging mandates |

| Europe | 24% | 4.8% | Plastic replacement initiatives |

| Latin America | 5% | 9.3% | Agricultural export packaging |

E-commerce packaging dominates consumption at 38%, followed by industrial wrapping solutions (27%), food-grade applications (19%), and specialty uses like construction vapor barriers (16%). Conversion rates for sustainable packaging alternatives reached 22% in the last two years, with duplex kraft paper capturing 73% of these conversions due to its recyclability credentials. Production output has increased by 1.2 million metric tons since 2020 to meet environmental compliance deadlines in major consumer markets.

Comparative Analysis of Leading Global Suppliers

Manufacturers exhibit distinct capabilities across quality benchmarks, service areas, and specialization niches. Based on comprehensive supplier evaluations across 12 performance dimensions, key differentiators emerge:

| Manufacturer | Production Capacity (tons/year) | Certifications | Specialized Offerings | Lead Time (days) |

|---|---|---|---|---|

| GlobalPack Solutions | 250,000 | FSC, ISO 14001, FDA | Food-grade barrier coatings | 10-12 |

| EcoMaterial Group | 180,000 | ISO 9001, BRCGS, OK Compost | 90-100% recycled content | 14-16 |

| Northern Paper Mills | 320,000 | SFI, PEFC, ISO 22000 | Heavy-duty (400+ GSM) | 8-10 |

| Alliance Packaging | 150,000 | Halal, Kosher, REACH | Custom print-ready surfaces | 12-15 |

Minimum order quantities (MOQ) vary significantly - large-scale manufacturers typically require 5-10 ton commitments for standard products, while niche players accept 1-2 ton MOQs for specialized formulations. Value-added services increasingly differentiate suppliers, with top performers offering complimentary packaging design consultations, material testing laboratories, and inventory management programs that maintain buffer stocks for key clients.

Customizable Solutions for Industry-Specific Requirements

Premium manufacturers develop application-engineered formulations by modifying core material properties:

- E-Commerce Optimization: Anti-slip textured surfaces with scuff-resistant coatings reduce in-transit damage by 27%; lightweight grades (180-200 GSM) provide sufficient protection while lowering dimensional weight charges

- Food Contact Formulations: Grease-resistant treatments meet FDA 21CFR standards; integrated antioxidant properties extend fresh produce shelf-life by 3-5 days; mineral-oil barrier layers prevent contamination

- Industrial Applications: High-tensile variants (bursting strength 500+ kPa) withstand sharp-edged components; static-dissipative treatments protect electronic assemblies; hydrophobic coatings maintain integrity at 95% humidity levels

- Specialty Requirements: Flame-retardant treatments achieve UL94 V-0 classification; biodegradable adhesives for compostable packaging systems; thermally insulating air-cellular structures for temperature-sensitive shipments

Technical collaboration begins with requirement assessments analyzing supply chain conditions, environmental exposures, and end-user handling characteristics. Prototyping processes typically require 3-4 weeks for custom formulations, with performance validation through ISTA-certified testing protocols.

Real-World Application Scenarios Across Industries

Automotive sector leaders have adopted reinforced duplex kraft for wrapping engine components, reducing packaging material consumption by 40% compared to plastic alternatives while improving recyclability. A European manufacturer reported 18-month ROI after switching, citing elimination of plastic disposal fees and reduced material costs. Heavy machinery suppliers utilize puncture-resistant grades that withstand 300kg point loads, significantly decreasing transit damage claims.

In food distribution, modified atmosphere packaging (MAP) formats preserve perishables through micro-perforated duplex paper that regulates oxygen transmission rates. One organic produce distributor achieved 92% reduction in spoilage losses through optimized paper configurations. Retail packaging conversions demonstrate consumer appeal - brands switching to premium print surfaces observed 17% higher shelf engagement in consumer studies, with tactile finishes increasing product perceived value.

Construction material protection represents an emerging application, where vapor-permeable wraps prevent moisture damage during building material storage. Manufacturers report weather exposure resistance up to 90 days without significant degradation. Electronics manufacturers particularly benefit from ESD-safe versions that maintain <1x10^9 ohm surface resistance throughout product lifecycles.

Why Choose Professional Duplex Kraft Paper Suppliers and Exporters

Establishing relationships with specialized duplex kraft paper manufacturers ensures access to technically advanced material solutions unavailable through standard distribution channels. Market-leading mills maintain dedicated R&D divisions that continually develop proprietary treatments - their chemical barrier technologies for example have progressed through 5 generations in the past decade alone. These research investments translate to performance improvements that support packaging engineers solving increasingly complex supply chain challenges.

Compliance management represents another critical value area as environmental regulations rapidly evolve. Professional manufacturers invest in comprehensive certification portfolios (typically 6-12 international standards) and implement chain-of-custody tracking through platforms like FSC Transparent. This infrastructure positions clients to meet emerging Extended Producer Responsibility (EPR) requirements efficiently. Leading suppliers also provide localization strategies for international supply chains through regional fulfillment centers that shorten lead times by 7-10 days.

Technical partnerships with manufacturers provide strategic advantages through supply chain optimization. Packaging engineers report 22% material savings through structural consultations that right-size packaging specifications without compromising protection properties. Sustainability guidance helps organizations navigate complex compliance landscapes while achieving environmental targets - documented cases show 41% lower carbon footprints versus alternative packaging materials when factoring in production energy, transportation weight, and end-of-life processing. These partnerships create resilience through verified secondary sourcing options and proactive risk management planning.

(duplex kraft paper)

FAQS on duplex kraft paper

Q: What is duplex kraft paper?

A: Duplex kraft paper is a two-layered kraft-based paper bonded together for enhanced strength and barrier properties. It is durable, eco-friendly, and often used in heavy-duty packaging like boxes, sacks, and envelopes. Common grades include white or brown finish for versatile industrial applications.

Q: How can I find reliable duplex kraft paper suppliers?

A: Start by searching online B2B platforms like Alibaba or Thomasnet for verified duplex kraft paper suppliers. Evaluate them based on certifications (e.g., ISO), sample quality, and delivery timelines. Aim for suppliers with strong customer reviews and flexible order quantities to ensure consistency.

Q: Who are the top-rated duplex kraft paper manufacturers?

A: Leading duplex kraft paper manufacturers include companies like Mondi Group, WestRock, and International Paper, known for global production scales and innovation. They offer customizable options in GSM weight, coatings, and reel sizes. Check industry reports or trade associations like PITA for vetted manufacturers.

Q: Why source from duplex kraft paper exporters?

A: Duplex kraft paper exporters specialize in cross-border trade, handling logistics, customs duties, and compliance for seamless shipments. They provide access to cost-competitive global markets, often with bulk discounts and quality assurances. This simplifies importing for buyers needing consistent supply chains at competitive prices.

Q: What are the key applications of duplex kraft paper?

A: Duplex kraft paper is primarily used in packaging for heavy items like machinery, furniture, and automotive parts due to its tear resistance. It also serves in labels, interleaving sheets, and as moisture-proof liners. Industries like e-commerce, food, and logistics rely on it for sustainable, protective solutions.

Latest news

-

Discover High Quality Self Adhesive Paper for Cabinets – Durable, Sustainable, Stylish

NewsNov.24,2025

-

Premium High Quality Blue Contact Paper for Furniture | Durable Surface Solutions

NewsNov.23,2025

-

What Drives High Quality Duplex Paper Price? Key Factors and Global Insights

NewsNov.22,2025

-

High Quality Decorative Contact Paper for Cabinets | Durable & Stylish Solutions

NewsNov.22,2025

-

High Quality Stick Paper for Cabinets: Durable, Sustainable, and Stylish Surface Solutions

NewsNov.21,2025

-

High Quality Self Adhesive Cabinet Paper: Durable, Sustainable Finishes for Modern Cabinets

NewsNov.20,2025