- Home

- Duplex Board Paper: Coated, High Stiffness, Eco

Nov . 07, 2025 12:25 Back to list

Duplex Board Paper: Coated, High Stiffness, Eco

What Buyers Really Need to Know About Duplex Board Paper in 2025

I spent a chilly morning last winter walking a converting floor in Xingtai, Hebei. Forklifts, ink smell, stacks of boards. The takeaway? Good packaging board still wins deals on print fidelity and stiffness—simple as that. Shineway’s Duplex board with Brown Back sits right in that sweet spot, and to be honest, it’s been gaining traction in footwear, bakery, and beauty cartons.

Industry snapshot

Global demand for Duplex Board Paper is creeping up despite cost pressures. Buyers want: higher CIE whiteness for CMYK accuracy, better water resistance for humid logistics, and credible certifications. Surprisingly, many customers say lead time reliability now beats tiny price differences.

Process flow (how it’s really made)

- Materials: recycled fibers (OCC/mixed waste) for the base; selected virgin pulp top layer for print; optional mineral coating.

- Methods: multi-ply sheet formation → online sizing → LWC/HWC coating → calendaring → sheeting (common sizes 1092×787, 1194×889, 610×860 mm, 31×43").

- Testing: grammage (ISO 536), moisture (ISO 287), stiffness (ISO 2493), Cobb water absorption (ISO 535), opacity (ISO 2471), brightness/whiteness (ISO 2470/11475).

- Service life: around 12–24 months in 20–25°C, 50–60% RH, boxed; real-world use may vary with warehouse conditions.

- Industries: shoe boxes, food & cake boxes, cosmetics, FMCG sleeves, pharma secondary packaging.

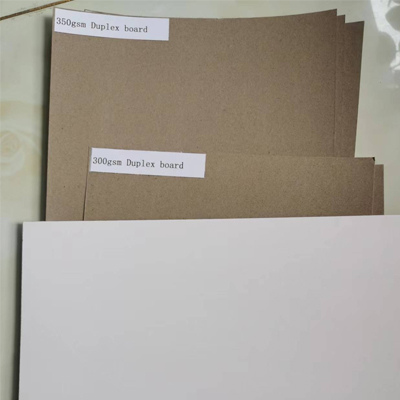

Product specs (Duplex board with Brown Back, Xingtai City, Hebei, China)

| Basis weight | 230–450 gsm (ISO 536) |

| Caliper | ≈ 300–650 μm (typical) |

| Stiffness (MD/CD) | Varies by gsm; e.g., 350 gsm ≈ 6.5/3.5 mN (ISO 2493) |

| Brightness/Whiteness | ISO Brightness ≈ 84–88%; CIE ≈ 95–105 (top side) |

| Opacity | ≥ 95% (ISO 2471) for most gsm |

| Cobb (60s) | Top ≤ 30 g/m²; back ≤ 50 g/m² (ISO 535), HWC lower |

| Moisture | 6.5–8.5% (ISO 287) |

| Back/Coating options | Brown back; also White/Gray back & White/White back, LWC/HWC |

| Formats | Sheets & reels; common sizes listed above |

Data are typical; test lots may vary within standard tolerances.

Applications and why it works

- Shoe boxes: high stacking strength; crease without fiber cracking when scored correctly.

- Food & cake boxes: clean print; food-contact compliance on request (FDA 21 CFR, GB 4806.8).

- Cosmetics: smooth top coat handles spot UV, foil, and 175–200 LPI CMYK nicely.

Advantages? Print latitude, predictable die-cutting, and stable moisture profile. Actually, converters tell me waste rates drop a bit on HWC tops.

Vendor comparison (quick buyer’s table)

| Vendor | Range | Back/Coats | Lead time | Certs | Customization |

|---|---|---|---|---|---|

| Shineway (Xingtai) | 230–450 gsm | Brown, White/Gray, White/White; LWC/HWC | ≈ 2–4 weeks | ISO 9001/14001; FSC on request | Sizes, reels/sheets, pallets |

| Vendor A | 250–400 gsm | White/Gray; LWC | 3–6 weeks | ISO 9001 | Limited sizes |

| Vendor B | 300–500 gsm | White/White; HWC | 4–8 weeks | FSC, ISO 22000 | Premium finishes |

Customization, QA, and real feedback

Custom runs: special sheet sizes, tighter Cobb, or food-contact compliance packs (migration tests) can be arranged. Typical QA includes reel moisture mapping, stiffness by lot, and color delta E checks. One cosmetics house told me their delta E dropped below 2.0 after switching to HWC—small but visible on pastel cartons.

Mini case notes

- Shoe brand, Vietnam: switched 350 gsm brown-back; carton waste fell ≈6% due to cleaner creasing.

- Bakery chain, Middle East: moved to 300 gsm HWC top; print density improved and smudging complaints nearly vanished.

Bottom line: if you need dependable Duplex Board Paper for boxes that print well and ship safely, this Xingtai-made grade is a very sane choice. Not flashy. Just consistent.

Authoritative references

- ISO 536: Paper and board — Determination of grammage.

- ISO 287: Paper and board — Determination of moisture content.

- ISO 2493-1: Determination of stiffness (Taber method).

- ISO 535: Paper and board — Determination of water absorptiveness (Cobb method).

- ISO 2471: Paper and board — Determination of opacity (diffuse reflectance).

- ISO 2470-1 / ISO 11475: Brightness/Whiteness measurement standards.

- FDA 21 CFR 176.170/176.180 — Components of paper in contact with aqueous/fatty foods.

- GB 4806.8-2016 — Chinese standard for paper materials in contact with food.

Latest news

-

Discover High Quality Self Adhesive Paper for Cabinets – Durable, Sustainable, Stylish

NewsNov.24,2025

-

Premium High Quality Blue Contact Paper for Furniture | Durable Surface Solutions

NewsNov.23,2025

-

What Drives High Quality Duplex Paper Price? Key Factors and Global Insights

NewsNov.22,2025

-

High Quality Decorative Contact Paper for Cabinets | Durable & Stylish Solutions

NewsNov.22,2025

-

High Quality Stick Paper for Cabinets: Durable, Sustainable, and Stylish Surface Solutions

NewsNov.21,2025

-

High Quality Self Adhesive Cabinet Paper: Durable, Sustainable Finishes for Modern Cabinets

NewsNov.20,2025